I am manually balancing the cells. I have not written the automatic algorithm yet. I figured I would do it manually to make sure I knew what to do. Note, that I am not using a charge controller at all. The BMS disconnects or connects the solar panels to the battery. The only benefit to balancing is to get the max capacity from the whole pack.

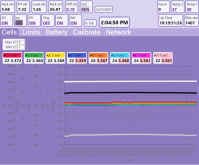

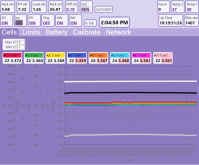

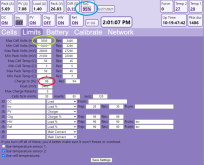

The battery is being run to the cell limit (green), instead of stopping at a % (red) and you can see it is in the run-up mode because the SoC (blue) is grayed. Note PV is ON.

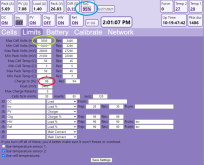

Cells 3, 4, 5, 6, and 7 have each been the top cell so they are all running their resistors for a day to bring them below the next highest. At 20ohms a day of burning drops about 4ah from the cell. I will keep repeating until I have seen all 8 cells at the top. Then I will repeat with maybe an 8 hour burn and after I have seen all 8 be the top cell, they should all be within 1ah of each other. That seems close enough.

The battery is being run to the cell limit (green), instead of stopping at a % (red) and you can see it is in the run-up mode because the SoC (blue) is grayed. Note PV is ON.

Cells 3, 4, 5, 6, and 7 have each been the top cell so they are all running their resistors for a day to bring them below the next highest. At 20ohms a day of burning drops about 4ah from the cell. I will keep repeating until I have seen all 8 cells at the top. Then I will repeat with maybe an 8 hour burn and after I have seen all 8 be the top cell, they should all be within 1ah of each other. That seems close enough.