SignatureSolarJames

Try Solar, the Grid will always take you back

All, I just want this thread out there if people have concerns about PV capacity annd how the MPPTs are supposed to work on the 18Kpv

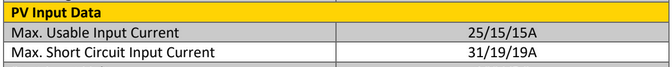

We have:

-1x 25A input

-2x15A inputs

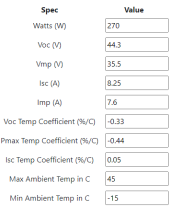

Both of these are max voltage open circuit (VOC ) of 600v, always derate for colder temperatures as the name plate VOC on a panel is at 77 degrees F, in texas I typically leave 40v of space, some climates need more, there is a temperature coefficient on each panel spec sheet that shows what % of voltage is increased per degree Celsius ( just use the 9/5 or 1.8 rule to rationn the F to C if you need)

Panels are facing a huge shift right now, the base cell sizes are frankly quite similar across manufacturers. 4 years ago the market was run by the M1 cell, then the split M6 cell arrived and this year the M10 cell will debut and is already in a lot of newer modules you may have noticed are in the 44 inch width now vs the classic 39/40 inch wide.

All this is to say that panels amperage per module is going up and will continue to increase

The M1 cells made panels around 9 amps, the m6 broke the 10 amp mark and the m10 is at the 11.5amp range

Here are 3 types of panels in each cell category and how I would string them:

-Canadian Solar 540W M10

-Canadian solar 400w all black M6

-Aionrise 360W all black M1

Canadian solar 540W m10

This is a 13Amp panel, so 1x string on the small inputs and 2x on the large (26A vs 25 is safely under the 1.2x clipping recommendations)

That leaves us with 4 strings of panels at 49VOC, the max string length is 11 in texas and may be 10 in colder places, let’s go with 10

4x10x540 = 21.6kW of PV

I running voltage is 400v then total amps of 13+13+25=51A x 400v = 20400 dc watts utilized, above the 18k needed for max utilization

Note the 410w class solarever and others coming soon are in this range too

Canadian solar 400w m6

11.44 amps per panel VOC is 44 so 12 string is 530VOC, safe for most everybody

This is closer as I would say that clippage is high if you try to double 2x strings on the 15A inputs, we always want to keep under 1.2 ratio here as you can run the numbers and find it is 1% total loss or less, going to 1.3 in a sunny climate takes another 1% off yearly production

So 4x 12 x400 w = 19.2kW of PV, if you use this style of panel

Aionrise 360w M1

OK, this gets more interesting, because the amps are 9.9 per panel (the highest M1 I have seen) you can actually put 3x on the 25 input and be under 1.2 amperage ratio (30/25A)

So 5 strings of 360, 11 long (540VOC) =55x360= 19.8kW of solar

If you are in a low light area or if you are adding more solar just as a hedge on cloudy days you can go above 1.2 ratio on the amperage and the total amount of solar will go higher. As an off-gridder I have been guilty of this a lot and it is a good idea many times if you are just trying to put more solar in vs adding batteries.

We have:

-1x 25A input

-2x15A inputs

Both of these are max voltage open circuit (VOC ) of 600v, always derate for colder temperatures as the name plate VOC on a panel is at 77 degrees F, in texas I typically leave 40v of space, some climates need more, there is a temperature coefficient on each panel spec sheet that shows what % of voltage is increased per degree Celsius ( just use the 9/5 or 1.8 rule to rationn the F to C if you need)

Panels are facing a huge shift right now, the base cell sizes are frankly quite similar across manufacturers. 4 years ago the market was run by the M1 cell, then the split M6 cell arrived and this year the M10 cell will debut and is already in a lot of newer modules you may have noticed are in the 44 inch width now vs the classic 39/40 inch wide.

All this is to say that panels amperage per module is going up and will continue to increase

The M1 cells made panels around 9 amps, the m6 broke the 10 amp mark and the m10 is at the 11.5amp range

Here are 3 types of panels in each cell category and how I would string them:

-Canadian Solar 540W M10

-Canadian solar 400w all black M6

-Aionrise 360W all black M1

Canadian solar 540W m10

This is a 13Amp panel, so 1x string on the small inputs and 2x on the large (26A vs 25 is safely under the 1.2x clipping recommendations)

That leaves us with 4 strings of panels at 49VOC, the max string length is 11 in texas and may be 10 in colder places, let’s go with 10

4x10x540 = 21.6kW of PV

I running voltage is 400v then total amps of 13+13+25=51A x 400v = 20400 dc watts utilized, above the 18k needed for max utilization

Note the 410w class solarever and others coming soon are in this range too

Canadian solar 400w m6

11.44 amps per panel VOC is 44 so 12 string is 530VOC, safe for most everybody

This is closer as I would say that clippage is high if you try to double 2x strings on the 15A inputs, we always want to keep under 1.2 ratio here as you can run the numbers and find it is 1% total loss or less, going to 1.3 in a sunny climate takes another 1% off yearly production

So 4x 12 x400 w = 19.2kW of PV, if you use this style of panel

Aionrise 360w M1

OK, this gets more interesting, because the amps are 9.9 per panel (the highest M1 I have seen) you can actually put 3x on the 25 input and be under 1.2 amperage ratio (30/25A)

So 5 strings of 360, 11 long (540VOC) =55x360= 19.8kW of solar

If you are in a low light area or if you are adding more solar just as a hedge on cloudy days you can go above 1.2 ratio on the amperage and the total amount of solar will go higher. As an off-gridder I have been guilty of this a lot and it is a good idea many times if you are just trying to put more solar in vs adding batteries.

Last edited: