Everything is going smoothly right now. Outside temps have dropped below 100*, so the entire system is working flawlessly. I haven't switched back to grid power in over a week now, and I wake up every morning to the battery around 30-50% still. I have 16 more cells on order to make a 2P16S battery now, and am going to individually charge/capacity test every cell I have to group high/low batteries as best I can. the compression fixture/mounting system will be pretty cool when I'm all said and done as well.

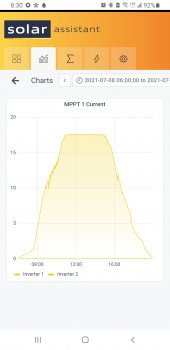

What I do find a little disappointing is how the LV6548's have a max 8000 watt PV Input, but I can't get better than 4500 "actual" watts due to PV configuration of the panels I have. Currently I'm running a 2x 6s2p, which makes 150v VMP and 13-14a IMP on each string. I can't step up to a 7s because VOC gets to 263v, 13v over the VOC limit, and stepping up to a 3p makes it clip at 18a, which again, wastes PV production.

I wish I could series connect the optimum number of my panels (22 panels making ~550v VMP) with fewer wire runs, then have some sort of step down converter at the LV6548 to step down to an optimal voltage range (200-230v). This would yield 550v VMP X 7a IMP = 3850 actual usable watts PER PV INPUT. Is this possible?

Sorry if I seem a little scrambled. I can see it all in my head, but have troubles putting it to words lol.