Hi all,

I will be building this system next week and wanted to thank all the help I’ve gotten from this forum.

I’ve attached a final blueprint for the system (excluding the solar and AC panel box). I’m planning to have approximately 60 to 80 of the Santan solar 240w panels. Five 6S strings into a combiner box for each of the two Growatt SC48120-MPV charge controllers. VOC will be 223.2V versus 250VDC max. Also three 6S strings into the Growatt SPF 3000TL LVM-ES.

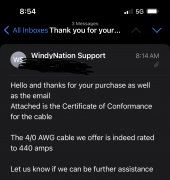

Both charge controllers and the inverter are connected to a BlueSea 600A 8-pole busbar. I used Windy Nation ANL fuses 120A (charge controller) and 100A (inverter). And 2 AWG welding cable.

The five 14kw battery packs are LiFePo4 cells (3.2v 280Ah) arranged 16S. They have the 100A Overkill Solar BMS and I’m using 2/0 cable. I have 200Amp breakers for each battery positive wire but I may need to get a 120Amp breaker instead. I don’t want it tripping too easily because then it will overload the other packs.

All five battery packs are paralleled onto separate BlueSea 600A 8-pole busbars. These battery busbars are connected to the inverter/charge controller busbar by 4/0 wire. This 4/0 has Bluesea 400A Class T fuse on the positive wire and Victron 500A Smartshunt on the negative wire.

Inside the enclosed trailer I plan to ground the three combiner boxes, panel box, and the trailer frame to an 8ft copper bar outside the trailer. The three combiner boxes will be inside the enclosed trailer.

The solar panels will be grounded separately to an 8ft copper bar.

Any thoughts are greatly appreciated!

View attachment 106173