I have a few acres of remote land, but with no power (nor water, but that's a separate topic). I put up two sheds, which I'll just call BLUE SHED and GREY SHED (they are both about 10'x10', small stuff).

It's an evolving work in progress. What I have works for me, though I would like an extra set of eyes for any "safety" concerns.

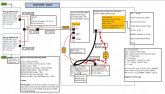

I have some simple not-to-scale connection diagrams attached below.

BLUE SHED: overview

- 2x300W panels that are remote from the shed (mounted on poles). (I actually have 5 of these, but one of them was severely cracked in shipping. Long story short, I got a partial refund for the damage since that was cheaper/simpler than a complicated return - I nursed that 5th panel back to health with basically some clear epoxy, and that 5th panel is what ended up on the other shed discussed later. The two other panels ended up for a different project, but here I just wanted to focus on these two shed projects.).

- The tail ends out of the panels are marked 12 AWG, but I used 10 AWG wiring throughout the rest of the connections

- I used Y-Connectors to connect these panels in parallel - I confess to being too cheap to put a fuse on each tail, and opted for a single 20A after the Y-connector (also since it's a small system and I think those fuses are overkill anyway -- as down the line, I have a 20A circuit breaker also as a quick disconnect, and the CC itself has an external 25A fuse).

- Between the CC BATT. connectors and the battery, yes I have a 50A breaker. I started with a 40A but I think it went bad, so I'm temporarily using a 50A and plan to reduce it down to a 30A breaker. Any issue there?

- Between the battery and inverter, I don't have a fuse yet. I have ANL fuses on the order. Do I take inverter 3000W peak / 12V = 250A, apply x1.25 just because, so then should I target a 300A fuse there? Or is there some other rule of thumb here?

- So why am I using 2/0 AWG between the battery and inverter? Well, the first cable I used was maybe 2AWG and there was a time when I physically felt it getting warm. That concerned me. After reading a bit, the maxAmps per cable size seems a little subjective (based on temperature and tolerances). I did 2000/12 and settled on "rounding" to 175A, which I think 2/0 AWG can handle. Any advise here? These thick copper cables get quite expensive. I do get a little confused here, because with 2x75AH batteries, does that mean the max "push" should be 150Amps? Or probably it doesn't work that way. In any case, the cables don't get warm any more, not that I've noticed.

- So speaking the batteries: this set is a couple cheap-o Duracell NG-24 deep cycle (despite "NG-24" or DC24 or SLI24MDC designators, they are actually 12V batteries). It was never completely clear, but I think I had determined that their rated usage was 75AH.

- The inverter could boil water, but struggled a bit with a microwave. So I just use it for basic things - drills, vacuuming, lights, etc. -- roughly limiting it to 5Amps draw. I think the portable induction oven I tried pushed 8 Amps in some modes.

- Thoughts? I estimate it all retail roughly $1200. As with both these sheds, I just use things lightly on the weekends, not daily survival.

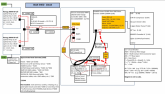

GREY SHED: overview

- Similar general arrangement as above, except 1x 300W (the left over repaired one as described above). In this case, the panel is roof mounted, hence the shorter line distance to the CC. I didn't read about or see any obvious Fuse for the Renogy CC, so I'm not sure what it has internally for fuses. I kept a 10A fuse to the PV, but so far don't have any inline circuit breaker switches.

- Renogy CC MPPT instead of Victron. They both have pros and cons, but overall I'd say I prefer the Victron for being more compact.

- Battery here, 2x100AH AGM deep cycles in parallel for total 200AH. Roughly speaking, the little AC unit uses about 5Amps, so I expected it be able to run at least 1 day on these battery. I haven't yet been able to verify that, the longest I have run them is about 6 hours.

- There is a beefier inverter here, 2000W instead of 1500W. This inverter ran the AC and microwave at the same time. The JackHammer actually uses a little less than 2200W (maybe 1800W; whereas the Microwave uses a bit more than 700W)

- The cabling between battery and inverter is only 2 AWG. I've never felt them become warm so I leave them alone.

Thought here on this one?

It's an evolving work in progress. What I have works for me, though I would like an extra set of eyes for any "safety" concerns.

I have some simple not-to-scale connection diagrams attached below.

BLUE SHED: overview

- 2x300W panels that are remote from the shed (mounted on poles). (I actually have 5 of these, but one of them was severely cracked in shipping. Long story short, I got a partial refund for the damage since that was cheaper/simpler than a complicated return - I nursed that 5th panel back to health with basically some clear epoxy, and that 5th panel is what ended up on the other shed discussed later. The two other panels ended up for a different project, but here I just wanted to focus on these two shed projects.).

- The tail ends out of the panels are marked 12 AWG, but I used 10 AWG wiring throughout the rest of the connections

- I used Y-Connectors to connect these panels in parallel - I confess to being too cheap to put a fuse on each tail, and opted for a single 20A after the Y-connector (also since it's a small system and I think those fuses are overkill anyway -- as down the line, I have a 20A circuit breaker also as a quick disconnect, and the CC itself has an external 25A fuse).

- Between the CC BATT. connectors and the battery, yes I have a 50A breaker. I started with a 40A but I think it went bad, so I'm temporarily using a 50A and plan to reduce it down to a 30A breaker. Any issue there?

- Between the battery and inverter, I don't have a fuse yet. I have ANL fuses on the order. Do I take inverter 3000W peak / 12V = 250A, apply x1.25 just because, so then should I target a 300A fuse there? Or is there some other rule of thumb here?

- So why am I using 2/0 AWG between the battery and inverter? Well, the first cable I used was maybe 2AWG and there was a time when I physically felt it getting warm. That concerned me. After reading a bit, the maxAmps per cable size seems a little subjective (based on temperature and tolerances). I did 2000/12 and settled on "rounding" to 175A, which I think 2/0 AWG can handle. Any advise here? These thick copper cables get quite expensive. I do get a little confused here, because with 2x75AH batteries, does that mean the max "push" should be 150Amps? Or probably it doesn't work that way. In any case, the cables don't get warm any more, not that I've noticed.

- So speaking the batteries: this set is a couple cheap-o Duracell NG-24 deep cycle (despite "NG-24" or DC24 or SLI24MDC designators, they are actually 12V batteries). It was never completely clear, but I think I had determined that their rated usage was 75AH.

- The inverter could boil water, but struggled a bit with a microwave. So I just use it for basic things - drills, vacuuming, lights, etc. -- roughly limiting it to 5Amps draw. I think the portable induction oven I tried pushed 8 Amps in some modes.

- Thoughts? I estimate it all retail roughly $1200. As with both these sheds, I just use things lightly on the weekends, not daily survival.

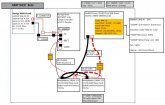

GREY SHED: overview

- Similar general arrangement as above, except 1x 300W (the left over repaired one as described above). In this case, the panel is roof mounted, hence the shorter line distance to the CC. I didn't read about or see any obvious Fuse for the Renogy CC, so I'm not sure what it has internally for fuses. I kept a 10A fuse to the PV, but so far don't have any inline circuit breaker switches.

- Renogy CC MPPT instead of Victron. They both have pros and cons, but overall I'd say I prefer the Victron for being more compact.

- Battery here, 2x100AH AGM deep cycles in parallel for total 200AH. Roughly speaking, the little AC unit uses about 5Amps, so I expected it be able to run at least 1 day on these battery. I haven't yet been able to verify that, the longest I have run them is about 6 hours.

- There is a beefier inverter here, 2000W instead of 1500W. This inverter ran the AC and microwave at the same time. The JackHammer actually uses a little less than 2200W (maybe 1800W; whereas the Microwave uses a bit more than 700W)

- The cabling between battery and inverter is only 2 AWG. I've never felt them become warm so I leave them alone.

Thought here on this one?