Interesting suggestion on the diode, like what is done for shaded PV panels.

The eBay listing is $15 each for used.

Here's same part number from DigiKey, different manufacturer. $81 each (pair) and rated 300A. So $162 for a 48V battery.

Order today, ships today. MBR30045CT – Diode Array 1 Pair Common Cathode Schottky 45 V 150A Chassis Mount Twin Tower from GeneSiC Semiconductor. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

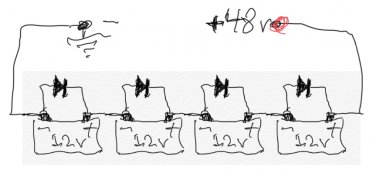

When one BMS disconnects, load will see 36V so hopefully doesn't draw current for long. Actually, if 3.6V per cell, 14.4V per battery, 43.2V from three batteries. That is above the 42V low voltage disconnect of my inverter set for lead-acid. Better have your low-voltage disconnect higher than that.

"

| Voltage - DC Reverse (Vr) (Max) | 45 V |

"

If all four BMS disconnect, you have four, 45V diodes in series with 56V being applied by SCC. In doing design, I avoid that because can't be certain how voltage will be distributed. If a diode breaks down due to over-voltage, it could present a short circuit when battery reconnects.

"

| Voltage - Forward (Vf) (Max) @ If | 650 mV @ 150 A |

"

That's 100W dissipation. Which is why I say you don't want load to continue drawing current after one battery disconnects; would need a good heatsink.

If you've used this diode scheme, have you put it through its paces, induced all the possible disconnect, charge, load configurations it has to handle?