Look up freezer temp controller. A johnson controller would work.

An upright freezer is another option, and they have a bottom drain for any coil condensation. I too am a home-brewer and have two of these, and two of the Johnson controllers - they're outstanding. I keep one at 65* for fermenting, also our bread, fruit, and alkaline batteries live in there. The other is at 33*, and holds up to four 'corny kegs', or 5gl beer kegs, with CO2 piped in, and taps in the door. Also takes overflow refer items from the big kitchen fridge.

The additional benefit of an upright is the ease of servicing and placing your lifepo cells. For me, lifting 6gl carboys over a chest freezer would be nigh impossible from past shoulder and back injuries.

These 'live' in my living room. Yes, we drink a lot of beer. LOL

Well, our friends do anyway.

Oh, and they've been running on a controller for the past four years, so compressor life doesn't appear to be an issue. They were both used freezers picked up off craigs, one was $100, the bigger one was almost new and $150. The controllers are about $60. You just set the freezer to full-cold. There are other more fancy electronic ones, but they cost more and I like the simple analog/mechanical approach to these. They're extremely reliable.

OTO, we just got one of those 5cubic foot chest freezers for extra storage in the garage, and it pulls 100w when it runs, about 20% duty cycle. At zero degrees F. Simply amazing. My Delta Mini can run it in a grid-down event.

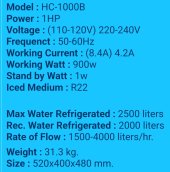

Controller...it plugs into the wall, the freezer plugs into the adapter plug, and the controller powers on the refer when it needs to cool:

My 'kegerators'...Browneye Brewing Co. ?