BMurray

New Member

- Joined

- Mar 13, 2021

- Messages

- 14

Ran a test this time with a more accurate temperature data logger. Used an Elitech RC-51 themometer that is designed mostly for monitor temperatures on shipments of perishable goods. It plugs into a USB port and the companies free software allows you to change several parameters. I set the unit to sample the temperature every 5 minutes. It has a metal disk at one end that is the sensor and a USB plug at the other end under a clear plastic cover.

I ran a test at 24 volts with the heating element mat sandwiched between one inch of XPS foam board (R5) and two inches of concrete paver. I placed the Elitech sensor side down against the stone and started the data recorder. Ran the power for five hours, simulating a winter days solar cycle. As expected it took longer for the heater to get up to temperature due to the larger mass, 2 inches rather than the previous 1 inch paver. I think the heater could have gotten hotter, but I shut it down after the five hours.

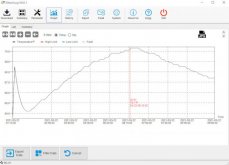

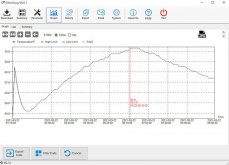

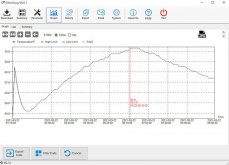

Below is a graph from the temperature sensor. It automatically creates a PDF file showing a graph and the individual data readings. And/or you can use the companies free software to graph the data on your computer.

The initial spike is my error, I had the sensor in my pocket before I placed it on the stone. Next time I will let it come to room temperature before starting. The red line is at 5 hours when I turned off the DC power. Another error, I should have let the recording run longer. Every indication I had was that the top of the stone had returned to room temperature of 65F. I will run the test again.

NOTE if you ever want to do long term recording of temperature you can buy these Elitech RE-51 data logging thermometers on Amazon for $33.

I think I will try this again but let the recorder run longer. Also looking forward to trying some PCM instead if the stone mass.

Thoughts? Suggestions?

I ran a test at 24 volts with the heating element mat sandwiched between one inch of XPS foam board (R5) and two inches of concrete paver. I placed the Elitech sensor side down against the stone and started the data recorder. Ran the power for five hours, simulating a winter days solar cycle. As expected it took longer for the heater to get up to temperature due to the larger mass, 2 inches rather than the previous 1 inch paver. I think the heater could have gotten hotter, but I shut it down after the five hours.

Below is a graph from the temperature sensor. It automatically creates a PDF file showing a graph and the individual data readings. And/or you can use the companies free software to graph the data on your computer.

The initial spike is my error, I had the sensor in my pocket before I placed it on the stone. Next time I will let it come to room temperature before starting. The red line is at 5 hours when I turned off the DC power. Another error, I should have let the recording run longer. Every indication I had was that the top of the stone had returned to room temperature of 65F. I will run the test again.

NOTE if you ever want to do long term recording of temperature you can buy these Elitech RE-51 data logging thermometers on Amazon for $33.

I think I will try this again but let the recorder run longer. Also looking forward to trying some PCM instead if the stone mass.

Thoughts? Suggestions?