You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

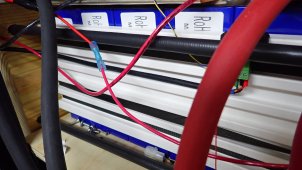

Very new to solar but started purchasing items, not sure of the final specs of the whole system.

- Thread starter kromc5

- Start date

Happen to find some very inexpensive 250v 3 pole shunt breakers. I was thinking of adding those to the pv inputs and allowing the batrium the ability to disconnect the pv inputs. This way the batrium has the ability to turn off both. I was wondering if this would be beneficial or not as additional safety precaution.

Last edited:

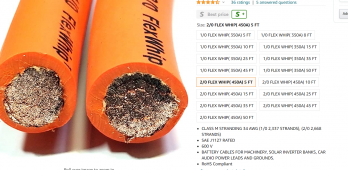

My preferred wire gauge calculator agrees with your assessment that the wire is overrated. I wonder how they came up with that.

I'm finding lots of those adds having it way overrated when I bought my 2/0 it was also overrated but not near as much.My preferred wire gauge calculator agrees with your assessment that the wire is overrated. I wonder how they came up with that.

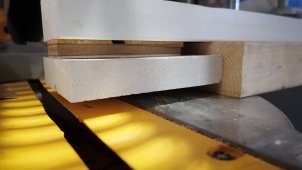

Thought I would show my improved jig for the copper. Having not worked with copper plate before I found it to be very grabby not sure how to describe it. My first jig had to much space and it was able to grab the cut side and fling it out. I made a new after that but wanted to show the idea. I intentionally left it long so the saw cut it flush and made it very tight. I have cut probably another 100+ bars with no issues. Also found the same issue with copper on the drill press it requires a much high load settings vs steel.

Attachments

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,504

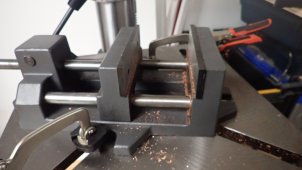

Make sure you're safe from injury if a work piece is grabbed and spun. Ideally a vice or something.

Have a dado blade? could make a notch to fit the busbar.

Could be a different bit, different grinding angle would perform better. Or a punch.

Have a dado blade? could make a notch to fit the busbar.

Could be a different bit, different grinding angle would perform better. Or a punch.

I have the drill press covered I have one the heaviest self-tightening vises and multiple self-tightening clamps. I hurt myself years ago playing in my grandfather’s garage drilling and rc chassis when I was very young. I'm just shocked how much more force it takes to do the tapping vs steel. I did make the mistake on the first few busbars not having that secure enough for the saw. So, I took the time to make it much safer with no clearance and flush with the saw to help. I wanted to show the idea incase anyone else uses a bevel saw to cut copper to beware of the issue.Make sure you're safe from injury if a work piece is grabbed and spun. Ideally a vice or something.

Have a dado blade? could make a notch to fit the busbar.

Could be a different bit, different grinding angle would perform better. Or a punch.

I had a piece get away from me on the drill press. I finally saw the light and bought a good quality drill press vise. No more accidents.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,504

I've also had a table saw chuck a board into my gut. Later, into a patio window (it is single-pane now).

I got a push stick for splitting lumber (like 2x4 --> 2x2), but don't like that it requires pushing down toward the blade.

I've finally realized I should make a pusher that rolls on opposite side of rip fence, with a piece that reaches over the fence and passes near blade.

Drill press is still a problem for some work pieces. I've had close calls.

I got a push stick for splitting lumber (like 2x4 --> 2x2), but don't like that it requires pushing down toward the blade.

I've finally realized I should make a pusher that rolls on opposite side of rip fence, with a piece that reaches over the fence and passes near blade.

Drill press is still a problem for some work pieces. I've had close calls.

I had a piece get away from me on the drill press. I finally saw the light and bought a good quality drill press vise. No more accidents.

I learned quickly how dangerous a drill press can be very early, and cutting copper which I will stick with the term grabby. Here's my setup vise is 32lbs you can get bigger but not in quick adjust with self tightening.I've also had a table saw chuck a board into my gut. Later, into a patio window (it is single-pane now).

I got a push stick for splitting lumber (like 2x4 --> 2x2), but don't like that it requires pushing down toward the blade.

I've finally realized I should make a pusher that rolls on opposite side of rip fence, with a piece that reaches over the fence and passes near blade.

Drill press is still a problem for some work pieces. I've had close calls.

Attachments

I've also had a table saw chuck a board into my gut. Later, into a patio window (it is single-pane now).

I got a push stick for splitting lumber (like 2x4 --> 2x2), but don't like that it requires pushing down toward the blade.

I've finally realized I should make a pusher that rolls on opposite side of rip fence, with a piece that reaches over the fence and passes near blade.

Drill press is still a problem for some work pieces. I've had close calls.

I used a set of Board Buddies on my table saw. Handy little wheels. They draw the board into the fence, keep it pressed down against the table and don't let the board move in reverse. Of course, if you screw up just right, the Board Buddies aren't going to save you.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,504

That's OK to prevent kickback, but I need a safe pusher too.

I'm not a fan of table saws they always make me nervous when using, I would consider only a saw stop but do not have the room. I use the dewalt track saw for all my long cuts. My cousin borrows a contractor table saw and did not have any support at all for the boards. I told him to be very careful and use a pusher and have the boards supported. The next evening, he had to get two fingers reattached.

So from the previous test and ongoing, I was very curious to see the pull from the battery vs the ac output amps. Just slightly double what is being pulled from the battery vs ac output.. The load has been between 18 to 60 amps the units fan does turn on but rarely. I can feel no warm spots on the outside of the inverter.

Last edited:

Also very impressed with growatt support they are very helpful and returned my call. I asked Kevin with help in getting the information to try and setup the batrium to the inverter. I will update on any progress in getting that up and running.

Wife turned the stove on, added little over 50 amp draw.

Interesting to watch the 60-70 amp loads pull the battery down and then back up it goes, look at the time stamps from the above till now.

The first cell with the dual negative connections shows 3.303, the positive with dual connections is 3.311, the bulk of the batteries are all 3.311 to 3.309. The lowest one is the very first cell on the negative side connection.

The load is now down to around 24 amps, this is two fridges, two freezers, tv and pc small fan, ac output is slightly less than half.

This inverter will have 14 of the 500watt bifacial when I get the replacements. Starting at 4:00pm I switched over to the inverter, having only 8 panels online did not produce enough when I tested the stove or dryer. I will be interested to see the kwh made when I have all the panels online.

Wife turned the stove on, added little over 50 amp draw.

Interesting to watch the 60-70 amp loads pull the battery down and then back up it goes, look at the time stamps from the above till now.

The first cell with the dual negative connections shows 3.303, the positive with dual connections is 3.311, the bulk of the batteries are all 3.311 to 3.309. The lowest one is the very first cell on the negative side connection.

The load is now down to around 24 amps, this is two fridges, two freezers, tv and pc small fan, ac output is slightly less than half.

This inverter will have 14 of the 500watt bifacial when I get the replacements. Starting at 4:00pm I switched over to the inverter, having only 8 panels online did not produce enough when I tested the stove or dryer. I will be interested to see the kwh made when I have all the panels online.

Last edited:

Similar threads

- Replies

- 52

- Views

- 4K