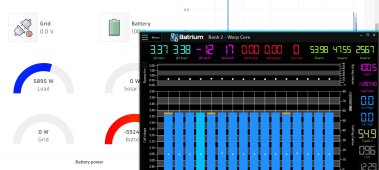

Almost complete I have two partial rows of 24 bifacials up and waiting for the replacements to finish.

Doing well with loads today with clear skies. Some more pics of the like new panels with minor blemishes I will be selling for

extremely overly inflated pricing. Amazing that some many shipments are damaged and completely destroyed pallets. I take lots of scrap to my local recycler but they refused the panels due to glass.

Doing well with loads today with clear skies. Some more pics of the like new panels with minor blemishes I will be selling for

extremely overly inflated pricing. Amazing that some many shipments are damaged and completely destroyed pallets. I take lots of scrap to my local recycler but they refused the panels due to glass.