You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Volatage drop

- Thread starter RobbieD

- Start date

mikefitz

Solar Wizard

- Joined

- May 28, 2020

- Messages

- 2,978

The Victron battery protect is a fet bases low loss one way switch that disconnects loads when the battery volts fall below protection volts.

Using the input post of the BP to feed the inverter is not a problem, although using a positive buss bar for cable connections is ideal.

Regarding the volt drop , all parts in the feed to the inverter can Introduce drops, do you have overcurrent protection , fuses or breakers, and any isolator switch?

Mike

Using the input post of the BP to feed the inverter is not a problem, although using a positive buss bar for cable connections is ideal.

Regarding the volt drop , all parts in the feed to the inverter can Introduce drops, do you have overcurrent protection , fuses or breakers, and any isolator switch?

Mike

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,843

Yes have a 200amp circuit breaker very close to the batteriesThe Victron battery protect is a fet bases low loss one way switch that disconnects loads when the battery volts fall below protection volts.

Using the input post of the BP to feed the inverter is not a problem, although using a positive buss bar for cable connections is ideal.

Regarding the volt drop , all parts in the feed to the inverter can Introduce drops, do you have overcurrent protection , fuses or breakers, and any isolator switch?

Mike

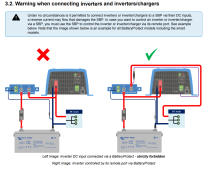

Yes, I have the inverter connected as per image on the right.From Victron BP user manual:

View attachment 150834

mikefitz

Solar Wizard

- Joined

- May 28, 2020

- Messages

- 2,978

Measure the drop across the breaker, any breaker even the high quality products, have significant drop at high currents, suggest using a fuse, at 12v a MRBF, in a Blue Sea holder is OK, or ideal, classT or HRC fuse, rated for DC . As discussed the actual current may be higher than 200 amps at inverter full power, consider a higher value, ( subject to adequate cables)

Mike

Mike

Last edited:

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,563

You should use a fuse instead of a breaker for high power 12v inverters. Most high current breakers have a lot of series resistance compared to a fuse.

It is not uncommon for a 250 amp breaker to have 3 to 5 milliohms of series resistance. 4 milliohms at 200 amps is 0.8v drop across breaker.

A fuse will have 0.5 milliohm to 1 milliohm of series resistance at 200 amps.

It is not uncommon for a 250 amp breaker to have 3 to 5 milliohms of series resistance. 4 milliohms at 200 amps is 0.8v drop across breaker.

A fuse will have 0.5 milliohm to 1 milliohm of series resistance at 200 amps.

Here is a good way to test where your problem connects are…

Start running your system at a high but sustainable load. Then put your fingers on everything. You will feel some place’s getting warm. That heat is resistance and voltage drop. You can also use a digital Multimeter and see what the voltage drop is at that connection.

Fix the issues and retest. I agree you probably need thicker cable or double up what you have.

Good Luck

Start running your system at a high but sustainable load. Then put your fingers on everything. You will feel some place’s getting warm. That heat is resistance and voltage drop. You can also use a digital Multimeter and see what the voltage drop is at that connection.

Fix the issues and retest. I agree you probably need thicker cable or double up what you have.

Good Luck

Awesome, will definitely test breaker. CheersMeasure the drop across the breaker, any breaker even the high quality products, have significant drop at high currents, suggest using a fuse, at 12v a MRBF, in a Blue Sea holder is OK, or ideal, classT or HRC fuse, rated for DC . As discussed the actual current may be higher than 200 amps at inverter full power, consider a higher value, ( subject to adequate cables)

Mike

Yes great idea. I can even use my thermal imager for this. Also agree, cables will need to change. I was thinking of pulling out the existing and going for 73mm2 welding cable but, as suggested above, it will be easier to run another of the same 53mm2 cables.Here is a good way to test where your problem connects are…

Start running your system at a high but sustainable load. Then put your fingers on everything. You will feel some place’s getting warm. That heat is resistance and voltage drop. You can also use a digital Multimeter and see what the voltage drop is at that connection.

Fix the issues and retest. I agree you probably need thicker cable or double up what you have.

Good Luck

mikefitz

Solar Wizard

- Joined

- May 28, 2020

- Messages

- 2,978

On reading your initial post again it suggests you are using the lithium batteries to start the vehicle.

Questions,

What vehicle?

How does the vehicle alternator 'play' with the batteries?

Is the battery negative connected to vehicle metal/ chassis/ frame?

What is the total BMS current discharge limit?

The concept of vehicle starting with lithium batteries can have issues:

Alternator failure due to overheating from high charge currents, or from BMS disconnect.

Lack of enough current from batteries for engine starting.

Low temperature lithium charging.

Possible vehicle electronics damage after BMS disconnect.

Mike

Questions,

What vehicle?

How does the vehicle alternator 'play' with the batteries?

Is the battery negative connected to vehicle metal/ chassis/ frame?

What is the total BMS current discharge limit?

The concept of vehicle starting with lithium batteries can have issues:

Alternator failure due to overheating from high charge currents, or from BMS disconnect.

Lack of enough current from batteries for engine starting.

Low temperature lithium charging.

Possible vehicle electronics damage after BMS disconnect.

Mike

HarryN

Solar Enthusiast

Just for fun, did you use the blue sea voltage drop calculator using the round trip wire lengths?

It isn't the one way - it is the entire length of the cable from the + to - terminal of the battery.

To be honest, I would not expect what you are doing to work. That battery to inverter distance is just too far for a 12 volt system.

You also do not have sufficient battery capability to deliver that kind of power reliably. For that level of power, normally I would use 4 batteries like that - 3 minimum.

_________

What will work is:

1) Go back to a conventional starter battery.

2) Locate the Li batteries within a few feet of the inverter. Ideally add at least one more battery.

3) Use a battery to battery charger like a sterling or similar to charge the Li batteries from the starter battery / veheicle electrical system.

Unfortunately there is a lot of misinformation out there on how to do van electrical systems the way that you did it and this concept did work for simple arrangements 30 years ago, but it doesn't work with modern vehicles and inverters of this power level.

It isn't the one way - it is the entire length of the cable from the + to - terminal of the battery.

To be honest, I would not expect what you are doing to work. That battery to inverter distance is just too far for a 12 volt system.

You also do not have sufficient battery capability to deliver that kind of power reliably. For that level of power, normally I would use 4 batteries like that - 3 minimum.

_________

What will work is:

1) Go back to a conventional starter battery.

2) Locate the Li batteries within a few feet of the inverter. Ideally add at least one more battery.

3) Use a battery to battery charger like a sterling or similar to charge the Li batteries from the starter battery / veheicle electrical system.

Unfortunately there is a lot of misinformation out there on how to do van electrical systems the way that you did it and this concept did work for simple arrangements 30 years ago, but it doesn't work with modern vehicles and inverters of this power level.

Similar threads

- Replies

- 7

- Views

- 310

- Replies

- 0

- Views

- 145

- Replies

- 2

- Views

- 154

- Replies

- 2

- Views

- 280