CoyotesDenHomestead

New Member

Hi guys, we are living in two fifth wheel trailers on our property (2 Parcels at 3.2 acres each) for the next year or so waiting for houses to get built, already been here 8 months.

Right now we have 3 gas generators, one on moms trailer, one on mine and one for the well, burned up several generators already through the hot AZ summer.

I am trying to decide which solar to go with, I have my eye on the MPP LV6548 but have concerns about my well pumps and a/c units on it.

I plan on using this system on the new house if it ever gets built as well. Solar Equipment will be housed in a shipping container for now.

My loads:

2 x 50amp Trailers - Each has two a/c units running hard during the day and some at night.

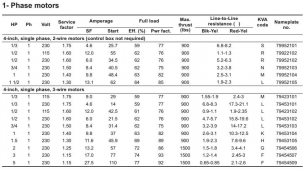

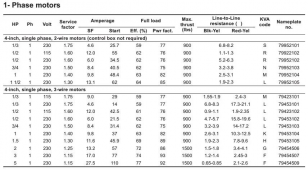

1 x 3HP Submersible Well Pump 600' Deep - Runs once a week for several hours - Could keep this on generator.

1 x 2HP Pressure Pump - Runs for a min or two several times a day.

1 x Full Size Refrigerator

1 x Washing Machine, we line dry.

1 x Starlink Internet 24/7 - Right now I have it on an 100ah LifePo4 Battery connected to a Lithium RV Charger on one of the generators.

1 x (future)Mini Split a/c & heat for the Shipping Container to maintain safe temps for equipment.

What do you think would be best and any tips?

I rather build this right the first time.

Right now we have 3 gas generators, one on moms trailer, one on mine and one for the well, burned up several generators already through the hot AZ summer.

I am trying to decide which solar to go with, I have my eye on the MPP LV6548 but have concerns about my well pumps and a/c units on it.

I plan on using this system on the new house if it ever gets built as well. Solar Equipment will be housed in a shipping container for now.

My loads:

2 x 50amp Trailers - Each has two a/c units running hard during the day and some at night.

1 x 3HP Submersible Well Pump 600' Deep - Runs once a week for several hours - Could keep this on generator.

1 x 2HP Pressure Pump - Runs for a min or two several times a day.

1 x Full Size Refrigerator

1 x Washing Machine, we line dry.

1 x Starlink Internet 24/7 - Right now I have it on an 100ah LifePo4 Battery connected to a Lithium RV Charger on one of the generators.

1 x (future)Mini Split a/c & heat for the Shipping Container to maintain safe temps for equipment.

What do you think would be best and any tips?

I rather build this right the first time.