AlbaCORPS

New Member

- Joined

- Jul 17, 2021

- Messages

- 16

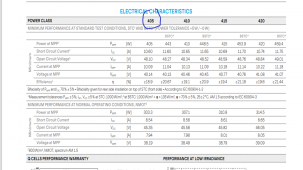

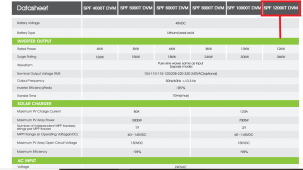

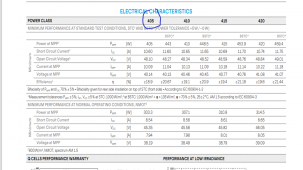

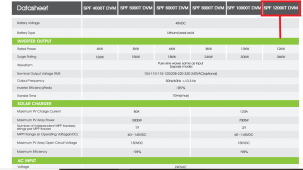

I'm looking to do my best set-up for (20) Q-cell 405w panels to a Growatt 12kW inverter. Being a newb to all this & still learning, I'd sooner swallow pride than make any grave mistakes.

So my question..... Whats my way to hook all this together? How many in series/parallel for how many strings? I'll attach pics of specs if that helps

Any & input is appreciated & TIA

So my question..... Whats my way to hook all this together? How many in series/parallel for how many strings? I'll attach pics of specs if that helps

Any & input is appreciated & TIA