I have 8 panels

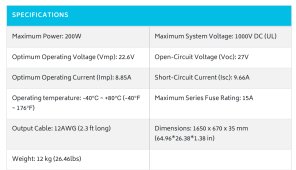

200 watts

27 VOC

9 amp (10-12 I would guess)

Should I run;

Series, 8x27=216 volts and 10-12 amps for 1600 watts

Or

Parallel, 8x10=12 volts and 80 amps for 1600 watts

I am still choosing my charge controllers…so I am looking at either 2 smaller ones or a one larger one

Am I thinking about this correct?

Thanks in advanced

200 watts

27 VOC

9 amp (10-12 I would guess)

Should I run;

Series, 8x27=216 volts and 10-12 amps for 1600 watts

Or

Parallel, 8x10=12 volts and 80 amps for 1600 watts

I am still choosing my charge controllers…so I am looking at either 2 smaller ones or a one larger one

Am I thinking about this correct?

Thanks in advanced