ericfx1984

Solar Enthusiast

- Joined

- Oct 10, 2021

- Messages

- 740

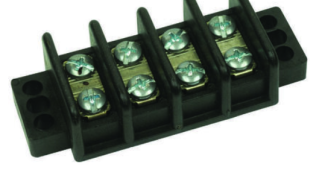

So I've been looking for an easy way to distribute power and or splice cabling ... In the past what I would do if I needed a splice cabling and a pinch is put a nice crimp connector on either end connect the crimps to each other and put a bolt through it of course insulating it with either electrical tape or preferably shrink tube

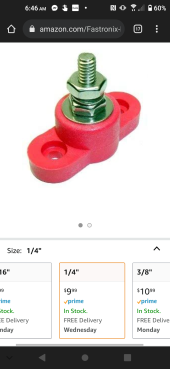

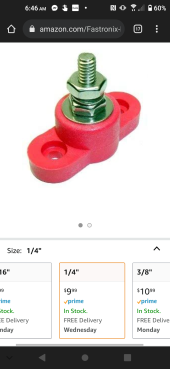

But then this thing comes along.. and that actually looks way more sturdy and way more convenient but I was curious why there's an amp rating on this.. in theory amperage should never be passing through it I mean yes there will be live voltage on it but there should be no actual current flow through the device all the current should be passing through the terminals... In short this is merely a fastening device and should handle whatever current the terminals and wire are handling right?

But then this thing comes along.. and that actually looks way more sturdy and way more convenient but I was curious why there's an amp rating on this.. in theory amperage should never be passing through it I mean yes there will be live voltage on it but there should be no actual current flow through the device all the current should be passing through the terminals... In short this is merely a fastening device and should handle whatever current the terminals and wire are handling right?