In my opinion, 0.05C at those temperatures is not going to cause any issues. The protection for low temperature cut-off however should be part of the BMS, not the charge controller, so you can always see if you can change setting there.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why you cannot charge LiFePO4 below 0 degrees Celsius

- Thread starter Will Prowse

- Start date

Low C charge rates aren't going to raise the battery temperature much. I charged mine at 70 amps and saw only a 2° F increase. The batteries were just below 45° F when I started charging

I have my BMS set to cut off charging at ~34° F but my charge controller is set to stop charging at ~32° F. Or something like that. The lower setting on the charge controller allows it to provide power to my heating pads without the heating pads drawing amps from the battery. At least that's the theory. My batteries haven't fallen below 35° F because that is the lowest temperature the thermostat will allow the batteries to fall before it kicks in the heating pads.

As with high/low voltage disconnect, the BMS has the last say. All other components know to stop charging/discharging before those thresholds are hit.

I have my BMS set to cut off charging at ~34° F but my charge controller is set to stop charging at ~32° F. Or something like that. The lower setting on the charge controller allows it to provide power to my heating pads without the heating pads drawing amps from the battery. At least that's the theory. My batteries haven't fallen below 35° F because that is the lowest temperature the thermostat will allow the batteries to fall before it kicks in the heating pads.

As with high/low voltage disconnect, the BMS has the last say. All other components know to stop charging/discharging before those thresholds are hit.

Thanks for the reply. My Batteries are cheap Chinese batteries (no low temp cut off) . They are all the exact same and wired to a bus bar with all the cables from the bus bar to the batteries the same length, so they all charge at the same rates.

I was wondering how I was not damaging my batteries and freaking out. I now know small current is fine, and once the small current is happening, the battery temperature defiantly rises. The Box is insulated and I have never seen it less than 15F in the box (when it is -16F outside).

I was wondering how I was not damaging my batteries and freaking out. I now know small current is fine, and once the small current is happening, the battery temperature defiantly rises. The Box is insulated and I have never seen it less than 15F in the box (when it is -16F outside).

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,623

Is that 0.05C battery charge current, perhaps reported by BMS?

Or, SCC output equal to 0.05C but feeding inverter and not going into battery?

Check your BMS specs and see if it is supposed to disconnect when it sees charge current while cold.

Some systems can make use of an internal or external shunt to measure battery current, control it while delivering current to loads.

That plus BMS temperature setting could protect batteries.

Below post has tables of charge current vs. voltage published for some cell brands.

I think the curves they represent are "equal degradation rate" lines. But some people seem to report colder charging without apparent damage, so I don't know.

diysolarforum.com

diysolarforum.com

Retrofitting/adding another BMS, perhaps connected to cells of just one battery but interrupting current for the bank, would serve to add temperature protection.

Or, SCC output equal to 0.05C but feeding inverter and not going into battery?

Check your BMS specs and see if it is supposed to disconnect when it sees charge current while cold.

Some systems can make use of an internal or external shunt to measure battery current, control it while delivering current to loads.

That plus BMS temperature setting could protect batteries.

Below post has tables of charge current vs. voltage published for some cell brands.

I think the curves they represent are "equal degradation rate" lines. But some people seem to report colder charging without apparent damage, so I don't know.

Why you cannot charge LiFePO4 below 0 degrees Celsius

...I glazed over...Soooo far past me...... but, does this mean that the claims of the -20F chargeable LiFePO4 cells could be true? Based on what i’ve read in this forum, not for any practical use. I’m no expert on the matter, though.

Thanks for the reply. My Batteries are cheap Chinese batteries (no low temp cut off) . They are all the exact same and wired to a bus bar with all the cables from the bus bar to the batteries the same length, so they all charge at the same rates.

Retrofitting/adding another BMS, perhaps connected to cells of just one battery but interrupting current for the bank, would serve to add temperature protection.

frosty_mp.pl

New Member

- Joined

- Apr 30, 2022

- Messages

- 1

OK, I uderstand well theory over why we should not attempt to charge LPO batteries in cold conditions. But in practical life, how do van owners manage this in winter time? It's cold for few consecutive days, it's sunny, PV produce great amount of power which is being lost? Heating baterries would help?

Yes. There are multiple threads on exactly that subject…OK, I uderstand well theory over why we should not attempt to charge LPO batteries in cold conditions. But in practical life, how do van owners manage this in winter time? It's cold for few consecutive days, it's sunny, PV produce great amount of power which is being lost? Heating baterries would help?

Sojourner1

Itinerant

Look in this section of the forum.OK, I uderstand well theory over why we should not attempt to charge LPO batteries in cold conditions. But in practical life, how do van owners manage this in winter time? It's cold for few consecutive days, it's sunny, PV produce great amount of power which is being lost? Heating baterries would help?

https://diysolarforum.com/forums/harsh-environment.12/

RandyP

Solar Enthusiast

- Joined

- Sep 21, 2019

- Messages

- 742

The info starts off "With the complex material system used in LIBs".This study summed it up nicely:

Source: https://www.sciencedirect.com/science/article/pii/S1002007118307536

LIBs include LFP batteries but are not limited to that one chemistry.

I think the article is a little misleading for those who do not differentiate between LIBs and LFP batteries clearly.

Michael Cantel

New Member

- Joined

- Nov 20, 2022

- Messages

- 1

In fact, in the cold winter in the north, the temperature is likely to be below 0 ℃. In order to solve this low temperature problem, some manufacturers provide two solutions:

One is to replace the conventional electrolyte with low-temperature electrolyte, so that the LiFePO4 battery can be used at low temperature.

The other is to add a heater plate between each battery cell and formulate relevant procedures in the battery BMS, so as to ensure that the overall temperature of the heated LiFePO4 battery is above 0 ℃.

So it is also possible to charge/discharge LiFePO4 Batteries at -20F, mainly depending on the scheme provided by the manufacturer.

One is to replace the conventional electrolyte with low-temperature electrolyte, so that the LiFePO4 battery can be used at low temperature.

The other is to add a heater plate between each battery cell and formulate relevant procedures in the battery BMS, so as to ensure that the overall temperature of the heated LiFePO4 battery is above 0 ℃.

So it is also possible to charge/discharge LiFePO4 Batteries at -20F, mainly depending on the scheme provided by the manufacturer.

...I glazed over...Soooo far past me...... but, does this mean that the claims of the -20F chargeable LiFePO4 cells could be true?

Last edited:

RandyP

Solar Enthusiast

- Joined

- Sep 21, 2019

- Messages

- 742

If the battery cells are at 32 deg F, you should not charge them. They can be held above the ambient temp of the air in the vicinity by adding heat to the batteries as noted. The ambient temp in the area might be -20, but the cells can be held above freezing with heated plates inserted between the cells/batteriess in the battery bank.In fact, in the cold winter in the north, the temperature is likely to be below 0 ℃. In order to solve this low temperature problem, some manufacturers provide two solutions:

One is to replace the conventional electrolyte with low-temperature electrolyte, so that the LiFePO4 battery can be used at low temperature.

The other is to add a heater plate between each battery cell and formulate relevant procedures in the battery BMS, so as to ensure that the overall temperature of the heated LiFePO4 battery is above 0 ℃.

So it is also possible to charge/discharge LiFePO4 Batteries at -20F, mainly depending on the scheme provided by the manufacturer.

Last edited:

Coydon

New Member

Reading through this thread to get a grasp on LFP thermal issues, I notice the unfortunate fact that almost every data point mentioned talks about 'the temperature of the battery', ignoring that what they are reading is actually the temperature of a sensor and rarely mentioning where it is placed.[emphasis mine]

due to thermal mass of battery and placement of temperature sensor resulting in the temperature sensor leading rather than lagging the cell material temperature?

less than 1C = 1CAmpere?

Looking at rocket mass heaters, it takes about an hour for the heat from a high temperature (~200-300*F) gas to conduct through an inch of the solid mass it flows through. Not trying to draw a direct comparison between current flow and heated gas, rather looking at how long it takes heat to conduct through a mass. Can anyone here explain the internal thermodynamics of these prismatic cells better?

Can anyone here explain the internal thermodynamics of these prismatic cells better?

The main context is that we're mostly interested in knowing when the battery is below 0C, or even more appropriate, somewhere around +5C. The reason for that is to prevent charging at low temperatures. Remember, 0C is not some hard cut-off temperature, it's more of a gradient - and the cell itself will work against the charging current as well because of increasing internal resistance. So once the temperature sensor drops below 5C, you stop charging. Once your sensor goes above, say, 7C, you re-enable charging. It might very well be that the actual cell at that moment is still colder, but if you have an insulated box, very unlikely to be much lower due to the same principles of thermal mass.

Where these aspects could be more important is at over-temperature protection, but with solar applications and their typically low C rates, these temperatures are again mostly driven by ambient changes. Usually, placing a temperature sensor in the same box with the cells (in case insulated) or glued somewhere to a cell in the middle of the pack if otherwise, gives a read-out that is perfectly fine for cell protection.

So, unlike rocket mass heaters, the temperature change is mostly externally driven, not coming from inside the mass.

Horsefly

Solar Wizard

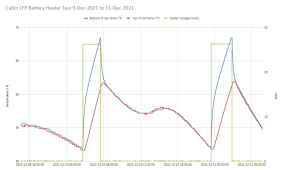

Here's a graph I posted over in my build thread that does explicitly show the temperature difference at different points on the cells.Reading through this thread to get a grasp on LFP thermal issues, I notice the unfortunate fact that almost every data point mentioned talks about 'the temperature of the battery', ignoring that what they are reading is actually the temperature of a sensor and rarely mentioning where it is placed.

Looking at rocket mass heaters, it takes about an hour for the heat from a high temperature (~200-300*F) gas to conduct through an inch of the solid mass it flows through. Not trying to draw a direct comparison between current flow and heated gas, rather looking at how long it takes heat to conduct through a mass. Can anyone here explain the internal thermodynamics of these prismatic cells better?

The heaters were under a 1/4" aluminum plate, and the cells were sitting on top of that plate. I had temperature measurements at the top of the aluminum plate (so about what the bottom of the cells were seeing) and at the top of the cells, furthest away from the heat. The green line shows when the heat was ON vs OFF. As you can see, the bottom of the cells (blue line) rose quickly and it took a while for the top of the cells (red line) to warm up. The thermostat was set to about 60°F on the top. The heat was on in both cases for right around three hours. By the time it turned off, the bottom of the sells was about 68°F while the bottom was about 61°F. It's also worth noting that temperature on the top of the cells kept going up for about 10-15 minutes after the heat had been turned off.

This is why I think it is much better to heat slowly, to make sure you don't cook the bottom of the cells before the top of the cells gets warm enough. My setup uses 24W of heat for 8 cells, and I'm happy with how it works.

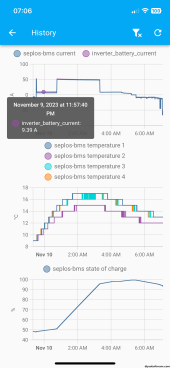

My Seplos BMS has a function to heat the battery while charging at low temperatures, but not a function so first heat and then charge. The only option is heating and charging at the same time, it seems to use about 3A for the heating pads and limit the current going to the battery to 6A (which for a 280Ah battery means 0.02C). Is it acceptable to charge the battery at such a small rate in subfreezing temperatures (while it heats up)?

My Seplos BMS has a function to heat the battery while charging at low temperatures, but not a function so first heat and then charge. The only option is heating and charging at the same time, it seems to use about 3A for the heating pads and limit the current going to the battery to 6A (which for a 280Ah battery means 0.02C). Is it acceptable to charge the battery at such a small rate in subfreezing temperatures (while it heats up)?

Can you set the temperature at which the BMS tries to heat the battery and then a separate parameter to turn off all charging when the temperature falls below that value? Are you sure that the BMS is limiting the charge amps? With most BMS, charging is either on or off, not throttled. I'm not familiar with the Seplos BMS.

I took the approach that I didn't want my batteries to charge at all below about 35°F. My heating pads are configured to keep the battery between 35°F and 45°F. This does not rely on the BMS. Within the BMS the low temp charge cutoff is set for about 32°F. This would kick in only if the warming pads were offline or unable to keep up. The charging devices (solar charge controller, inverter/charger) have similar settings to not charge below 32°F.

No, with the Seplos BMS there is no way to heat the battery before charging; it can only activate the pads during charge, not during standby or discharge. I have to chose between charging at a slow rate and heat up the battery at the same time or no charging at all and wait for warmer weatherCan you set the temperature at which the BMS tries to heat the battery and then a separate parameter to turn off all charging when the temperature falls below that value? Are you sure that the BMS is limiting the charge amps? With most BMS, charging is either on or off, not throttled. I'm not familiar with the Seplos BMS.

I took the approach that I didn't want my batteries to charge at all below about 35°F. My heating pads are configured to keep the battery between 35°F and 45°F. This does not rely on the BMS. Within the BMS the low temp charge cutoff is set for about 32°F. This would kick in only if the warming pads were offline or unable to keep up. The charging devices (solar charge controller, inverter/charger) have similar settings to not charge below 32°F.

The Seplos bms can throttle charging current; despite requesting 3kW charging, the inverter is only sensing 9A to the bms, then the Bms sends 6A to the cells and 3A to the pads

Last edited:

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,623

Does it have low-temperature cutoff and a different temperature for heating?

You might set it to start heating at 40F, cut off at 35F it temperatures keep dropping.

Of course, need a temperature difference it won't pass through during the night.

Use insulation.

You might set it to start heating at 40F, cut off at 35F it temperatures keep dropping.

Of course, need a temperature difference it won't pass through during the night.

Use insulation.

Horsefly

Solar Wizard

That seems like a pretty odd way for Seplos to manage the heating, but I'll take your word for it.No, with the Seplos BMS there is no way to heat the battery before charging; it can only activate the pads during charge, not during standby or discharge. I have to chose between charging at a slow rate and heat up the battery at the same time or no charging at all and wait for warmer weather

The Seplos bms can throttle charging current; despite requesting 3kW charging, the inverter is only sensing 9A to the bms, then the Bms sends 6A to the cells and 3A to the pads

I do something pretty similar to @HRTKD, managing the heating separate from the BMS. I thought I remembered looking at how the JK BMS with heating function worked, as well as how the Trophy battery worked. I have one of the heat-control-capable JK BMS's, and I've helped someone install a system with the Trophy batteries. The way I understood how they both worked is that they used one temperature setting that both cut off charging and turned on the heat. That seemed pretty suboptimal to me, but I guess it would work as long as the BMS is FET based. The discharge FETs would still be enabled, so the charge source would see the battery and could attempt to charge. However, that charge would only end up going to the heating circuit. Once the temperature got above the set point, the charge FETs would be enabled and the heating would be disabled. If it was actually cold, it seems like this would get into a tight loop of charge being turned on and off and the heating being cycled as well.

I ended up adding the little heating pads and thermostat like I have on my system to the Trophy batteries. The friend with those batteries will be visiting his cabin this wither, so I'm anxious to hear a report that it all worked as intended.

It has:Does it have low-temperature cutoff and a different temperature for heating?

You might set it to start heating at 40F, cut off at 35F it temperatures keep dropping.

Of course, need a temperature difference it won't pass through during the night.

Use insulation.

- charge low temperature protection: no charge and no heating below this temp

- charge low temperature alarm: reduced charge current below this temperature

- cell low temperature heating: heating pads on below this temperature but only if also charging at the same time (and not below low temperature protection)

Similar threads

- Replies

- 0

- Views

- 149

- Replies

- 60

- Views

- 4K

- Replies

- 6

- Views

- 487

- Replies

- 2

- Views

- 484