showme

New Member

I've just completed installing a grundforss sqflex pump and something is weird here. I have it wired direct (no batteries) to a series of (6) Evergreen Solar 120w panels. It was late afternoon when I finally got it wired and operational. The panels are on a temporary stationary ground mount I made. I can't remember what degree they're mounted, but it's basically winter position, not facing up to the summer alignment.

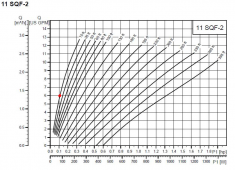

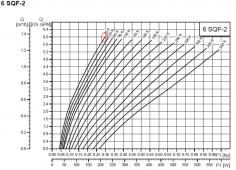

I've got them running through an old(er) Outback breaker box with a dual post 125a breaker that was in it, which came with a wind generator set up I bought used. So, I've got 720w of panels but the CU200 controller was showing 250w coming in at the time shown above. It was pumping a good 5.5gpm through the 6gpm Grundfoss even at .25kw, and I haven't made it back down to the property today to check in in mid day sun, but I was just wondering if running the panels through a double breaker instead of a single could affect the power coming out of that breaker? I realize I may get back down there tomorrow and get full power out of the array, but it made me think about something I'd never considered before. Thanks for any help on this. Lee

I've got them running through an old(er) Outback breaker box with a dual post 125a breaker that was in it, which came with a wind generator set up I bought used. So, I've got 720w of panels but the CU200 controller was showing 250w coming in at the time shown above. It was pumping a good 5.5gpm through the 6gpm Grundfoss even at .25kw, and I haven't made it back down to the property today to check in in mid day sun, but I was just wondering if running the panels through a double breaker instead of a single could affect the power coming out of that breaker? I realize I may get back down there tomorrow and get full power out of the array, but it made me think about something I'd never considered before. Thanks for any help on this. Lee