bookish

New Member

- Joined

- Mar 6, 2021

- Messages

- 13

I'm looking for thoughts and/or experiences protecting a PV ground mounted array from wind.

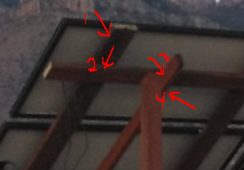

I just built this array in the picture, and want to protect it from wind damage. We do get very high winds there in SE Arizona.

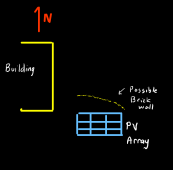

I'm considering building a brick wall on the north side, from the same adobes the building behind is made from. If I were to do that, I think some sort of curve in the wall would help from the standpoint of structural integrity as well as airflow characteristics. Anybody versed in fluid dynamics and such who could give advise? Any other way of doing it I'd also like to consider. I don't want to just attach a wall to the north-side uprights because then the stresses would just fall on that side of the frame instead of being taken off the frame, and I'm nervous about those footings being less than adequate.

Attaching a drawing of my idea for a possible wall footprint.

I just built this array in the picture, and want to protect it from wind damage. We do get very high winds there in SE Arizona.

I'm considering building a brick wall on the north side, from the same adobes the building behind is made from. If I were to do that, I think some sort of curve in the wall would help from the standpoint of structural integrity as well as airflow characteristics. Anybody versed in fluid dynamics and such who could give advise? Any other way of doing it I'd also like to consider. I don't want to just attach a wall to the north-side uprights because then the stresses would just fall on that side of the frame instead of being taken off the frame, and I'm nervous about those footings being less than adequate.

Attaching a drawing of my idea for a possible wall footprint.