gcp

Going nomadic.

- Joined

- Sep 1, 2021

- Messages

- 49

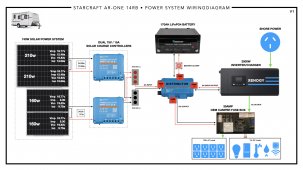

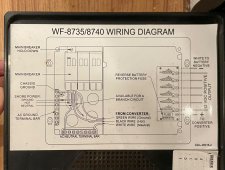

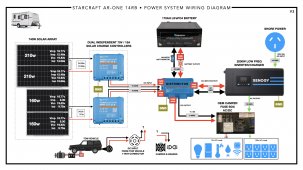

Hi! I bought my first camper and intend to do some off the grid camping with it. Other than working on my car, I knew very little about electrical systems before this. I've been doing a bunch of research and wanted to see how far it got me in terms of planning out my own system. Today I took a first stab at a wiring diagram to see if it's coming together, and if I actually understand what I'm doing. How am I doing so far? I don't know what fuses I need for my distributor yet. And I might need some in other places? I don't know if I actually need bus bars for my dual SCCs. I don't really understand how the Inverter/Charger works with the camper's existing power system yet. Feedback and guidance very much welcome and appreciated! Thank you