Maybe you might want to ask her what a "300kgf fixture" is while you're at it? Many of us are wondering about this. I'd ask myself, but you seem to be the liason here and we don't want too many people bugging her.

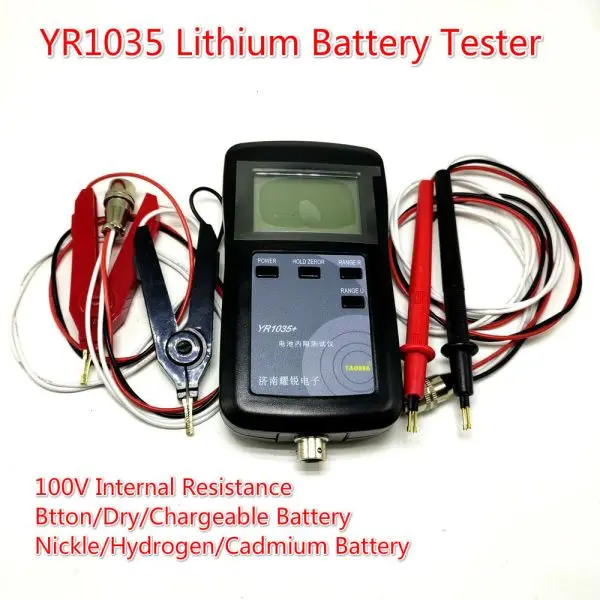

Yeah, they are the same meter.

Here is a video review in English. I did notice that some of the cheaper vendors I saw lacked the yellow "Yaorea" in the bottom right corner. Not sure if those are a knock off or what. Apparently it is also printed on the circuit board inside. And it looked to me like Xuba uses the version with the "upgraded leads." They are only a few dollars more.

Also, in case anyone else orders one, make sure it supports English menus. Apparently some of them do not.

@Denis Good to know someone here actually has one in hand and likes it. Thanks!

And could you provide an acutal link to the one you bought? I didn't see any that cheap.