WanderingAlbatross

New Member

- Joined

- Apr 21, 2020

- Messages

- 66

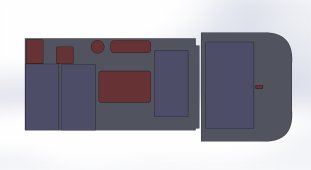

We are installing a single 400 watt panel on our Class C motorhome. The plan is to use 8 z-brackets and large expanding rivets into the fiberglass overcab.

I am wondering if there are any particular extra strength z-brackets people would recommend for such an installation. Is aluminum sufficient or do I need to go with stainless steel brackets? A bonus if they are low profile (<1" offset from the surface).

Thanks!

I am wondering if there are any particular extra strength z-brackets people would recommend for such an installation. Is aluminum sufficient or do I need to go with stainless steel brackets? A bonus if they are low profile (<1" offset from the surface).

Thanks!