chicagoandy

New Member

I'm in the process of acquiring the large Ruixu server rack. It's 10 48V 100Ah server racks assembled in parallel. It'll be paired with a Sol-Arc 15k.

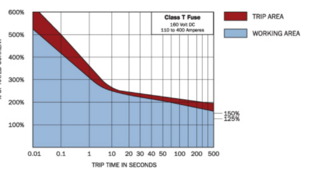

I'll be attaching a fuse to the rack for safety. Currently I'm planning a 350A class-T fuse, the Bussman JJN-350. This has an AIC of 20 kAIC at 160 Vdc, 200 kAIC at 300Vdc. Presumably the AIC is less at 52V.

My question is, with 10 large batteries in parallel, is the class-T even sufficient? It seems each of these large batteries could push out 2,000 amps in a failure? Or do we trust the BMS to keep each battery current more reasonable?

Are there other fuse types with even higher AIC?

What is the point at which large parallel batteries can have inrush beyond the capability of Class-T fuses?

I'll be attaching a fuse to the rack for safety. Currently I'm planning a 350A class-T fuse, the Bussman JJN-350. This has an AIC of 20 kAIC at 160 Vdc, 200 kAIC at 300Vdc. Presumably the AIC is less at 52V.

My question is, with 10 large batteries in parallel, is the class-T even sufficient? It seems each of these large batteries could push out 2,000 amps in a failure? Or do we trust the BMS to keep each battery current more reasonable?

Are there other fuse types with even higher AIC?

What is the point at which large parallel batteries can have inrush beyond the capability of Class-T fuses?