Checkthisout

Solar Wizard

- Joined

- Nov 14, 2021

- Messages

- 4,905

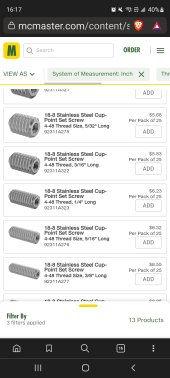

If it was me and I had to use them because you have no other options, I'd drill the battery post and the removed threaded post and tap them #4-48. Use stainless set screws to connect the two along with a conductive epoxy. The center "post" will give you the equivalent of a 11/10 AWG wire and the epoxy should give you a bump as well.

I weld and I would personally not ask someone to TIG that unless you know they are an expert. I've known maybe two people in 20 years I'd trust to TIG tack those on and hope the battery doesn't get dorked due to the heat. If I was going to TIG it, I'd drill small holes in the washer in 6-8 places equi-spaced. Then use a 1/16" tungsten to just bang spots on hoping to get adequate penetration into the base stud through the hole.

I would drill and tap, then stud then give a few quick zaps around the stud after cooling the battery overnight in the freezer.

I don't think the battery manufacturers that weld the busbars to the battery are using Lazer welds so I'm not sure why others on here don't think these can, if not tig welded, be spot welded on.