Doggydogworld

Solar Enthusiast

- Joined

- Aug 29, 2022

- Messages

- 360

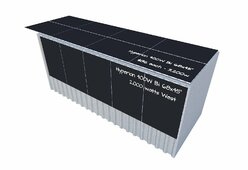

Anchored to concrete footings.....I should be able hookup 90kW of panels mounted a single 20ft shipping container according to this.

Anchored to concrete footings.....I should be able hookup 90kW of panels mounted a single 20ft shipping container according to this.

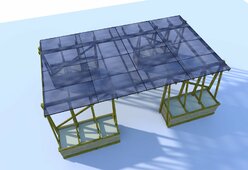

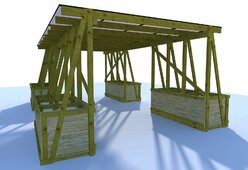

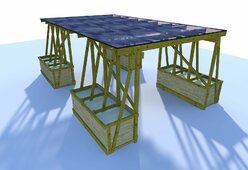

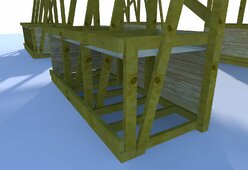

sketchup, then using a plugin called twilight for the renders.What program do you use to design these? Is it for computer?

Thanks. This a march project, so plan is to nail down a design on the sooner side, purchase the panels and PT wood so it can dry out for a few weeks, and build the 4 boxes with verticals attached first.I think it looks awesome and you should start building. It looks flat enough that wind shouldn't be to much of an issue.

You would change your ballast a bit, but I bet some veggies would grow really good in your bins if you tweaked your fill on top...

Again, not an engineer.

bad news. unfortunately it's going to cost too much, and way too much when I remember to factor in my time.Revised cost estimate?

the trailer is an option, but the roof isn't designed to support weight. roof is 7x14 i might be able to bracket from the edges but a used shipping container is my new path.Thinking we have all benefited from your work here.

Since we have not seen images of the site, it's hard to say if you could get by using gravel ballast ground mount tubs. They do provide angle for winter production.

You spoke of a trailer? Might you consider mounting solar panels on it? Could the panels provide some shade to the trailer? Once again not sure of your situation.

Yea, sorry I'm all over the place with the ideas. used shipping container(s) is still primary path. i am getting my inverter/batteries setup this weekend (this project was battery backup solution before solar) and then will pull the trigger on container 1 shortly after. I already sourced a few locally with delivery.Lol, that mobile deployment video you found must've got you thinking. I'm enjoying your brainstorming updates

There's a very good chance that the panels are fine and only the MC4 connectors will need to be replaced.my first thought is he must be referring to the MC4 connectors being corroded, in which case the panels should be fine if hardwired or refurbed with new connectors. right? somebody tell me i can be excited right now....

www.pairedpower.com

www.pairedpower.com

Quite frankly, I wish they had never chosen the MC4- it really isn't a good connector at all...There's a very good chance that the panels are fine and only the MC4 connectors will need to be replaced.

I got a couple of never used, awful looking panels that were 'stored' on the ground for about 6 years.

The MC4s had to be replaced and the panels washed - good as new

I've found it takes about a year for mismatched MC4s to break down, some may last longer but it's a hit and miss thing with "compatibility".Any MC4 over half a decade old should be inspected on a regular basis (once a year) for insulation deterioration (specifically the sealing ring inside- they harden from the heat and if exposed to the weather as most are, will fail and allow water inside, oxidising the copper connections and potentially leading to arcing on the contacts inside

i moved on from the pergola for cost/ labor solving wind load. snow would have been easier to solve but never got there.Where do you live because you are forgetting about snow load requirements. Likely 10-25 pounds per square foot....

20 foot X 18 foot is 360 sqft and at 10 lbs snow load is 3,600#'s

at 25 lbs snow load is 9,000 lbs. I don't think what you got will hold 9,000 lbs but it might hold 3,000...

You will need an engineer (PE) sign off on this.