BatteryNut

New Member

- Joined

- Aug 13, 2021

- Messages

- 20

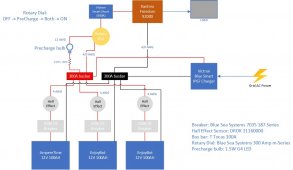

I'm looking to start a proper battery backup system instead of my current string of batteries tied to an inverter.

Currently, the planned loads are:

1) Sump pump, 280W running

2) Deep freezer, 60W running

3) IT Stack, 40W running (constant)

4) Wine fridge, 1.5W idle, 200W running

I have sourced all parts except the precharge bulb and the 4/0 wire.

If you have the time, please look over my design and the part selections and share your thoughts.

Your inputs are appreciated.

(jpg attached in case the pdf doesn't work for you. It works for me on my pc but not on my ipad)

Currently, the planned loads are:

1) Sump pump, 280W running

2) Deep freezer, 60W running

3) IT Stack, 40W running (constant)

4) Wine fridge, 1.5W idle, 200W running

I have sourced all parts except the precharge bulb and the 4/0 wire.

If you have the time, please look over my design and the part selections and share your thoughts.

Your inputs are appreciated.

(jpg attached in case the pdf doesn't work for you. It works for me on my pc but not on my ipad)

Attachments

Last edited: