kenkoh

Solar Enthusiast

Is one more efficient than the other if I have to run longer wires from PV to SCC?

This is such a first class detail response more than I hoped for thank you.Ken, I'm not sure if you're asking about 12V vs 24V panels or if you're asking about battery bank nominal voltage. The battery bank voltage doesn't directly come into play when looking at the PV voltage and wires so I'm going to assume that's not what you're after. So let's look at the relationship between your PV array and wire size along with pointing you to a tool that will let you model different options.

I'll take the HQST 150W panels from one of your 600W builds and use that as an example. The panel specs we'll use are:

I know you've been involved in discussions regarding putting panels in series vs. parallel and how that affects the voltage and amperage. You also know how to make sure your Voc of the array doesn't exceed the max voltage of the SCC (you and many others are now also aware of Voc maximums based on temperature thanks to this thread). Now let's take a look at using this voltage drop calculator tool to model a couple scenarios:

- Voc (open circuit voltage) = 22.7V

- Isc (short circuit current) = 8.09A

Scenario 1 - Your 600W setup with 4 150W panels in series:

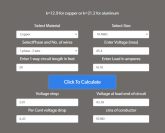

To simply things, we'll use the Voc and Isc directly from the panel label. The 4 panels in series would have a Voc of 4 x 22.7 = 90.8V (voltage is additive in series). The Isc of the series panels is 8.09A (current in series remains the same as a single panel). Let's go with an array that is 50 feet from your SCC. Plugging that info into the tool, along with selecting a 10 AWG wire size yields the following results. Note the voltage drop and percent voltage drop.

View attachment 8031

Scenario 2 - Modified 600W setup with the 4 panels in 2 series, 2 parallel configuration:

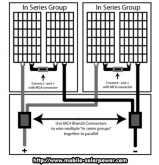

In this scenario, the solar panel configuration looks like this (courtesy of Will's mobile solar power website).

View attachment 8034

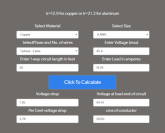

This changes our Voc to 2 x 22.7V = 45.4V and our Isc to 2 x 8.09A = 16.18A (current in parallel is additive). The same 50 foot distance yields the following results. Note the increased percent voltage drop.

View attachment 8033

Ultimately you want to keep the voltage as high as possible within the SCC limits and the current as low as possible to optimize efficiency. The size of the wire factors in as well since the larger the wire, the lower resistance and a lower voltage drop. Here's scenario 2 using 8 AWG instead of 10 AWG:

View attachment 8035

Hopefully this is helpful and gives you another tool to add to your arsenal when planning systems.

I know what you mean but to the unlearned this might sound like voltage controls resistance, "Always the higher the voltage the less the resistance. But this means the voltage from the panels to SCC. The battery voltage. Weather it be 12 or 24 will not affect the resistance between panels and SCC.

Is one more efficient than the other if I have to run longer wires from PV to SCC?

excellent ty!Ken, I'm not sure if you're asking about 12V vs 24V panels or if you're asking about battery bank nominal voltage. The battery bank voltage doesn't directly come into play when looking at the PV voltage and wires so I'm going to assume that's not what you're after. So let's look at the relationship between your PV array and wire size along with pointing you to a tool that will let you model different options.

I'll take the HQST 150W panels from one of your 600W builds and use that as an example. The panel specs we'll use are:

I know you've been involved in discussions regarding putting panels in series vs. parallel and how that affects the voltage and amperage. You also know how to make sure your Voc of the array doesn't exceed the max voltage of the SCC (you and many others are now also aware of Voc maximums based on temperature thanks to this thread). Now let's take a look at using this voltage drop calculator tool to model a couple scenarios:

- Voc (open circuit voltage) = 22.7V

- Isc (short circuit current) = 8.09A

Scenario 1 - Your 600W setup with 4 150W panels in series:

To simply things, we'll use the Voc and Isc directly from the panel label. The 4 panels in series would have a Voc of 4 x 22.7 = 90.8V (voltage is additive in series). The Isc of the series panels is 8.09A (current in series remains the same as a single panel). Let's go with an array that is 50 feet from your SCC. Plugging that info into the tool, along with selecting a 10 AWG wire size yields the following results. Note the voltage drop and percent voltage drop.

View attachment 8031

Scenario 2 - Modified 600W setup with the 4 panels in 2 series, 2 parallel configuration:

In this scenario, the solar panel configuration looks like this (courtesy of Will's mobile solar power website).

View attachment 8034

This changes our Voc to 2 x 22.7V = 45.4V and our Isc to 2 x 8.09A = 16.18A (current in parallel is additive). The same 50 foot distance yields the following results. Note the increased percent voltage drop.

View attachment 8033

Ultimately you want to keep the voltage as high as possible within the SCC limits and the current as low as possible to optimize efficiency. The size of the wire factors in as well since the larger the wire, the lower resistance and a lower voltage drop. Here's scenario 2 using 8 AWG instead of 10 AWG:

View attachment 8035

Hopefully this is helpful and gives you another tool to add to your arsenal when planning systems.

everytime i see even the most simple algebraic formula, my mouth goes dry, my eyes glaze over and i go to my happy place.For those that want some math.

The resistance of a wire is given by:

R = ρ * L / S

Meaning, the bigger the cross section (S) the lower the resistance and the longer the cable, the bigger the resistance. Rho (ρ) is the resistivity of the material the cable is made off, usually copper. So to get the lowest resistance, keep the cables short and thick.

Keeping in mind Ohm's law, we also know that the resistance is ratio of the voltage across the resistor and the current passing through the resistor.

R = U / I

In addition, Power is given by voltage and current as follows:

P = U * I

If we take Ohm's law and rewrite it as U = R * I and put that in the Power equation, we get:

P = R * I * I

or

P = R*I^2

This latter formula gives your actual cable losses due to heat when you take our very first formula into account. You can clearly see that in this formula, because of I^2, we see a rapid increase in losses at higher currents. For this reason, to optimally transfer your power, you want to increase the voltage and keep the current low to minimize losses in the cable.

everytime i see even the most simple algebraic formula, my mouth goes dry, my eyes glaze over and i go to my happy place.

Keep it up, we need some mathletes here!Math is (one of) my happy place(s)

LOL that's allright somebody's gotta do it, but algeBore isn't really math now is it? It uses lettters which makes it more like ... Minglish!Math is (one of) my happy place(s)

Why 8 AWG, can you tell me how long is your cable?I got 25% more Watts, going from 80VDC to 120VDC. Same 8AWG wire, one additional panel.

From 2s4P to 3s3P.

Higher Volts, AND Lower AMPS at the same time, and in the end more Watts.

but algeBore isn't really math now is it? It uses lettters which makes it more like ... Minglish!

Information I can use!I got 25% more Watts, going from 80VDC to 120VDC. Same 8AWG wire, one additional panel.

From 2s4P to 3s3P.

Higher Volts, AND Lower AMPS at the same time, and in the end more Watts.

how many watts was the one, additional panel and what was the combined wattage of the original panel array?Why 8 AWG, can you tell me how long is your cable?

on Saturday the 2x8 array was doing about 1400 watts when I added the additional panel and changed to 3x3 right away to 1800 watts.how many watts was the one, additional panel and what was the combined wattage of the original panel array?

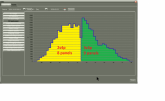

Very nice. Looks like you also achieved an extra 100 watts of, "throughput", by going from 80 to 120 VDC.on Saturday the 2x8 array was doing about 1400 watts when I added the additional panel and changed to 3x3 right away to 1800 watts.

View attachment 8054

Each panel is 295wHp (when new) These are about 6 years old.

Nicely presented.Ken, I'm not sure if you're asking about 12V vs 24V panels or if you're asking about battery bank nominal voltage. The battery bank voltage doesn't directly come into play when looking at the PV voltage and wires so I'm going to assume that's not what you're after. So let's look at the relationship between your PV array and wire size along with pointing you to a tool that will let you model different options.

I'll take the HQST 150W panels from one of your 600W builds and use that as an example. The panel specs we'll use are:

I know you've been involved in discussions regarding putting panels in series vs. parallel and how that affects the voltage and amperage. You also know how to make sure your Voc of the array doesn't exceed the max voltage of the SCC (you and many others are now also aware of Voc maximums based on temperature thanks to this thread). Now let's take a look at using this voltage drop calculator tool to model a couple scenarios:

- Voc (open circuit voltage) = 22.7V

- Isc (short circuit current) = 8.09A

Scenario 1 - Your 600W setup with 4 150W panels in series:

To simply things, we'll use the Voc and Isc directly from the panel label. The 4 panels in series would have a Voc of 4 x 22.7 = 90.8V (voltage is additive in series). The Isc of the series panels is 8.09A (current in series remains the same as a single panel). Let's go with an array that is 50 feet from your SCC. Plugging that info into the tool, along with selecting a 10 AWG wire size yields the following results. Note the voltage drop and percent voltage drop.

View attachment 8031

Scenario 2 - Modified 600W setup with the 4 panels in 2 series, 2 parallel configuration:

In this scenario, the solar panel configuration looks like this (courtesy of Will's mobile solar power website).

View attachment 8034

This changes our Voc to 2 x 22.7V = 45.4V and our Isc to 2 x 8.09A = 16.18A (current in parallel is additive). The same 50 foot distance yields the following results. Note the increased percent voltage drop.

View attachment 8033

Ultimately you want to keep the voltage as high as possible within the SCC limits and the current as low as possible to optimize efficiency. The size of the wire factors in as well since the larger the wire, the lower resistance and a lower voltage drop. Here's scenario 2 using 8 AWG instead of 10 AWG:

View attachment 8035

Hopefully this is helpful and gives you another tool to add to your arsenal when planning systems.

Nicely presented.Ken, I'm not sure if you're asking about 12V vs 24V panels or if you're asking about battery bank nominal voltage. The battery bank voltage doesn't directly come into play when looking at the PV voltage and wires so I'm going to assume that's not what you're after. So let's look at the relationship between your PV array and wire size along with pointing you to a tool that will let you model different options.

I'll take the HQST 150W panels from one of your 600W builds and use that as an example. The panel specs we'll use are:

I know you've been involved in discussions regarding putting panels in series vs. parallel and how that affects the voltage and amperage. You also know how to make sure your Voc of the array doesn't exceed the max voltage of the SCC (you and many others are now also aware of Voc maximums based on temperature thanks to this thread). Now let's take a look at using this voltage drop calculator tool to model a couple scenarios:

- Voc (open circuit voltage) = 22.7V

- Isc (short circuit current) = 8.09A

Scenario 1 - Your 600W setup with 4 150W panels in series:

To simply things, we'll use the Voc and Isc directly from the panel label. The 4 panels in series would have a Voc of 4 x 22.7 = 90.8V (voltage is additive in series). The Isc of the series panels is 8.09A (current in series remains the same as a single panel). Let's go with an array that is 50 feet from your SCC. Plugging that info into the tool, along with selecting a 10 AWG wire size yields the following results. Note the voltage drop and percent voltage drop.

View attachment 8031

Scenario 2 - Modified 600W setup with the 4 panels in 2 series, 2 parallel configuration:

In this scenario, the solar panel configuration looks like this (courtesy of Will's mobile solar power website).

View attachment 8034

This changes our Voc to 2 x 22.7V = 45.4V and our Isc to 2 x 8.09A = 16.18A (current in parallel is additive). The same 50 foot distance yields the following results. Note the increased percent voltage drop.

View attachment 8033

Ultimately you want to keep the voltage as high as possible within the SCC limits and the current as low as possible to optimize efficiency. The size of the wire factors in as well since the larger the wire, the lower resistance and a lower voltage drop. Here's scenario 2 using 8 AWG instead of 10 AWG:

View attachment 8035

Hopefully this is helpful and gives you another tool to add to your arsenal when planning systems.