Boron

New Member

Hi Guys - this is not a clickbait rubbish. Its my genuine attempt to overcome the serious MC4 problem - a demountable connection system that doesnt burn out on you.

So here is my Mk1 version

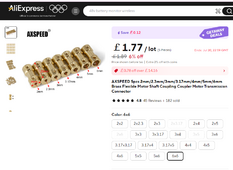

Solid brass mechanical straight coupling using 2 pairs of hex grub screws. The cable is standard 6mm2 solar TUV (10AWG). I hope the poor quality pix are self explanatory.

You could use a rubber tube (UV res) as a simple cover and squirt some Si grease in to keep water out. Or you can use a heatshrink sleeve if you dont expect to have to demount it (by stripping the sleeve - less convenient maybe.

Rated for 50A as per cable. Cost <$1. No crimping tool needed as the grub screw points and copper sleeve grip the strands tightly.

What do you think? Armchairs - do your worst

BTW I have no commercial interest - the design is offered as GNU for the benefit of Solar Members and saving on roof fires.

So here is my Mk1 version

Solid brass mechanical straight coupling using 2 pairs of hex grub screws. The cable is standard 6mm2 solar TUV (10AWG). I hope the poor quality pix are self explanatory.

You could use a rubber tube (UV res) as a simple cover and squirt some Si grease in to keep water out. Or you can use a heatshrink sleeve if you dont expect to have to demount it (by stripping the sleeve - less convenient maybe.

Rated for 50A as per cable. Cost <$1. No crimping tool needed as the grub screw points and copper sleeve grip the strands tightly.

What do you think? Armchairs - do your worst

BTW I have no commercial interest - the design is offered as GNU for the benefit of Solar Members and saving on roof fires.