Could the noise really be so bad they'd need 213 mV at the receiver? After all, AM/FM is in the μV; if your using an amplifier that just seems crazy... is this what happens when you put 7 EEs in a room? I need to re-read that several more times....

Maybe. Maybe also for convenience; when you don't want to have amps and filters and take the time to tweak all that perfectly right to get your signal out of the noise you just improve the SNR right at the transmitter

Wow, can't really compare that to radio/TV signals, that's a whole another can of worms with some black magic in it... ^^

Didn't mean to imply you were old, and I do understand what you mean... beauty is in the eye of the beholder and and the artistry of something tangible is far more evident then something intangible like s/w (which far to often isn't very pretty at all).

Yea don't worry, it was just that I wrote it in an ambiguous way so I thought it was a good idea to be more clear

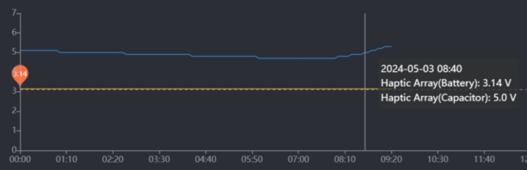

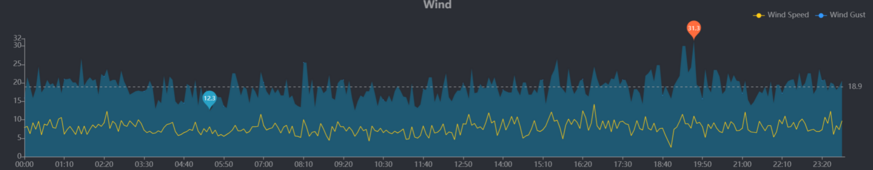

They're using the STM32F429 180 MHz chip, so that's 6 ns/cycle and should be fast enough for 1 mph wind speeds deltas.

Be careful about using the base clock for that kind of things, sometimes you can have big surprises.

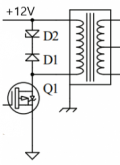

R5 and C3 allow discharging the energy stored in the transducer.

I'd say it's more a resonant circuit than anything else. You can omit them at the cost of the efficiency.

Then there's D2 is a zener diode and it causes the voltage induced by the primary of the transformer during its unloading to be 13 V? They say:

Yep, remember the old ignition coils with the mechanical contacts? they used a capacitor to avoid pitting them too fast, here they use a zener to avoid destroying the driver and/or MCU instantly ^^

Sounds suspiciously like magnetic magic, I get the transformer's magnetic field will resist the change in current flow but not how the zener is bumping the voltage up in combination with it. Tried simulating it (see attachment) but didn't see 13V... to many unknowns. Certainly the output transformer voltage didn't ramp up very fast.

It doesn't bump up the voltage, it's the opposite, it limits it. It's the same thing as why we put a diode in anti-parallel on a relay coil when it's driven by some electronics