So, what sort of dB would be generated at 3.3V and how many volts should the receiver see? Assuming I’m interpreting this correctly…

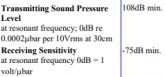

Datasheet Facts

Transmitting Sound Pressure Level at 40.0Khz; 108 dB min, 0dB re 0.0002Pbar per 10Vrms at 30cm

Receiving Sensitivity at 40.0Khz 0dB = 1 volt/μbar -75dB min.

From the

ref:

Determining SPL at the front end of Receiver

SPL loss for 3 Vrms driving voltage = 20 * log (3V / 10V) = -10.46 dB

SPL Gain at 10 cm = 20 * log (30 cm / 10 cm) = 9.54 dB

Wave absorption = ~ .1886 dB/m * .1 = .02 dB (

page 4)

The SPL at 10 centimeters becomes = 108 – 10.46 + 9.54 - .02 = 107 dB

Converting SPL to μbar: 107 dB = 20 * log ( X / 0.0002 μbar)

X = 45 μbar

Determining Receiver Sensitivity in Volts/μbar

Converting Sensitivity to Volt/μbar: -75 dB = 20 * log ( X / 1 Volt/μbar)

X = 0.178 mV/μbar

Voltage generated under 0.178 mV/μbar = 0.178 mV/μbar * 45 = 8 mV

At 5V it the receiver would be:

Determining SPL at the front end of Receiver

SPL loss for 3 Vrms driving voltage = 20 * log (5V / 10V) = -6.02 dB

The SPL at 10 centimeters becomes = 108 – 6.02 + 9.54 - .02 = 111.5 dB

Converting SPL to μbar: 107 dB = 20 * log ( X / 0.0002 μbar)

X = 75.16 μbar

Determining Receiver Sensitivity in Volts/μbar

Voltage generated under 0.178 mV/μbar = 0.178 mV/μbar * 75.16 = 13 mV

Update: The Cortex M7 ADC has 12 bits and covers -3.3 to 3.3, so steps of 1.6 mV? If so, wouldn't need a transistor to boost the receiver signal for a chirp, but to curve match we'd get a better fit with a transistor.