JReich2609

New Member

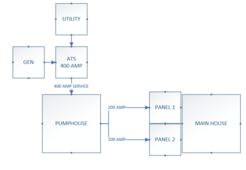

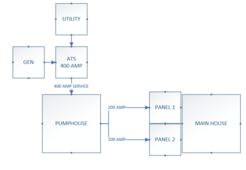

This is a quick and dirty drawing of the proposed wiring on new construction.

We have placed the Generator at the 400 AMP feed with an appropriately sized ATS because there is pumping equipment that needs to be powered in the event of a power outage in the pumphouse itself. So by having the power generator there we can feed down the system.

My question is where is the best place to hook solar into this system. Would I hook a Sol-Ark or example into each 200 AMP panel, or one that feeds both panels (if that is even possible). We don't have a real need/desire to store power for use this is just to offset use in real-time so likely an AC coupled system.

But my experience in this area is minimal so just looking for thoughts/insights. We have a reasonably high power demand so the system will be sized appropriately. And would having solar production and the generator running simultaneously be a problem? As in this design I am not sure if we'd need the GEN and SOLAR to talk to each other, or not?

Thanks all for your thoughts!

We have placed the Generator at the 400 AMP feed with an appropriately sized ATS because there is pumping equipment that needs to be powered in the event of a power outage in the pumphouse itself. So by having the power generator there we can feed down the system.

My question is where is the best place to hook solar into this system. Would I hook a Sol-Ark or example into each 200 AMP panel, or one that feeds both panels (if that is even possible). We don't have a real need/desire to store power for use this is just to offset use in real-time so likely an AC coupled system.

But my experience in this area is minimal so just looking for thoughts/insights. We have a reasonably high power demand so the system will be sized appropriately. And would having solar production and the generator running simultaneously be a problem? As in this design I am not sure if we'd need the GEN and SOLAR to talk to each other, or not?

Thanks all for your thoughts!