So, I just got ten 12 volt 100watt solar panels for a theoretical wattage of 1kw. The issue is that they have to be about 135 feet away from the rest of the system and I’m not sure how to get the power from there to my charge controller. I have done some calculations and I think I need 6 awg wire to go that far with the 83 amps that I calculated that the panels will put out. The issue is that I cannot find mc4 connectors for wire that big. Does anyone have any suggestions as to a solution to this problem?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to connect my solar panels?

- Thread starter myself3

- Start date

You do not want to wire the panels in 10P. But if you did you wouldn't need 83A MC4 connectors since you would have a big combiner box next to the panels so no MC4 connectors would be needed.

6AWG wire is way too small to run 83A 270 feet (round trip) at such low voltage. Even with 4/0AWG wire you would still have a 10% voltage drop over that distance. So it's not really an option.

You want as much voltage as you can and as little amperage as you can.

Start by posting the full specs for your panels and your charge controller.

Also, why 100W panels? 3 330W panels would have been so much simpler.

6AWG wire is way too small to run 83A 270 feet (round trip) at such low voltage. Even with 4/0AWG wire you would still have a 10% voltage drop over that distance. So it's not really an option.

You want as much voltage as you can and as little amperage as you can.

Start by posting the full specs for your panels and your charge controller.

Also, why 100W panels? 3 330W panels would have been so much simpler.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,844

Please post the spec of the panels and the spec of the charge controller.

Cajunwolf

Solar Enthusiast

Set up your solar panels in two strings of 500 watts each in a 5s2p configuration, that's 64 volts (12.8x5), and two 40amp Mppt controllers in parallel. If you calculate your amperage, you now have 7.8 amps instead of 83. You can run that with a suitable 20 amp extension cord. The MPPTs will bring the 64 volts back to the 12.8 volts for your batteries. I have a 24-volt system and have two strings of panels for a total of 1040 watts each (4x260 watts) with two MPPTs at 40-amps each. I found it cheaper to buy two 40 amp CCs than one 100 amp; shop around.

MichaelK

Solar Wizard

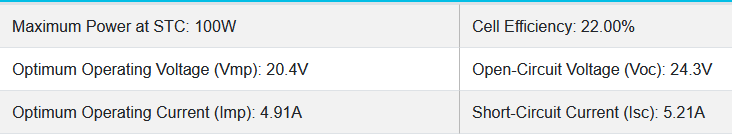

Where are you coming up with these numbers? About the only thing that you seem to get right is that two controllers are needed. Because no panel specs have been posted, we have to make an educated guess here. Let's look at a standard 100W panel like what Renogy sells....Set up your solar panels in two strings of 500 watts each in a 5s2p configuration, that's 64 volts (12.8x5), and two 40amp Mppt controllers in parallel. If you calculate your amperage, you now have 7.8 amps instead of 83. You can run that with a suitable 20 amp extension cord. The MPPTs will bring the 64 volts back to the 12.8 volts for your batteries. I have a 24-volt system and have two strings of panels for a total of 1040 watts each (4x260 watts) with two MPPTs at 40-amps each. I found it cheaper to buy two 40 amp CCs than one 100 amp; shop around.

With a Vmp of 20.4V, five in series would already be 102V, and the Voc 121.5V. And that's at room temperature. Right at freezing, the Voc is likely to bump up to ~134V. This will fry a budget controller like a Epever 4210AN. Even more conservative numbers for other panels that are in the 21-22Voc range, those will also surpass 100V even at room temperature, let alone cold weather.

This is doable, though you would need at least a 150V limit controller to handle the voltage. Assuming the 1000W of panels will be charging at 13V, then you'd expect to see (1000W/13V) X 85% derating = 65A, so either 1 80A controller, or two 40A are needed. Something like Epever's 8415AN is appropriate here.

The 100 watt panels were way less expensive. Here is a picture of the specs of the panels:You do not want to wire the panels in 10P. But if you did you wouldn't need 83A MC4 connectors since you would have a big combiner box next to the panels so no MC4 connectors would be needed.

6AWG wire is way too small to run 83A 270 feet (round trip) at such low voltage. Even with 4/0AWG wire you would still have a 10% voltage drop over that distance. So it's not really an option.

You want as much voltage as you can and as little amperage as you can.

Start by posting the full specs for your panels and your charge controller.

Also, why 100W panels? 3 330W panels would have been so much simpler.

And the charge controller is:

What do you mean by this? I’m kind of new at solar panels, and I’ve never heard of 10 p before.You do not want to wire the panels in 10P.

I’m planning on putting them in parallel so that the voltage stays the same, however I’m also considering doing a mix of both so that I get 24 volts because it’s easier to get that voltage to go this far, but I might need a step down transformer for that. I would also consider 4 awg wire for this.You should post your panel specs.

If you put them all in series the voltage will be over 200v can your charge controller handle that?

Last edited:

That sounds great except that my charge controller can only handle 48 v max. Also, what’s a 5s2p configuration?Set up your solar panels in two strings of 500 watts each in a 5s2p configuration, that's 64 volts (12.8x5), and two 40amp Mppt controllers in parallel. If you calculate your amperage, you now have 7.8 amps instead of 83. You can run that with a suitable 20 amp extension cord. The MPPTs will bring the 64 volts back to the 12.8 volts for your batteries. I have a 24-volt system and have two strings of panels for a total of 1040 watts each (4x260 watts) with two MPPTs at 40-amps each. I found it cheaper to buy two 40 amp CCs than one 100 amp; shop around.

That's not the specs. We need things like Voc, Vmp, Isc, and Imp. Post a link to the panels.Here is a picture of the specs of the panels

Again, not the needed specs. Post a link to the SCC.And the charge controller is

10P means 10 panels in parallel. Once you post links and the needed specs can be found, then recommendations can be made on the best panel setup.What do you mean by this? I’m kind of new at solar panels, and I’ve never heard of 10 p before.

That means 2 parallel strings of 5 panels in series each.Also, what’s a 5s2p configuration?

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,844

10p = 10 panels on parallel.

We need the spec of the panel, you only show the box, same for the charge controller.

The 48V is the rating of the battery/system Voltage not the PV input Voltage spec.

We need the spec of the panel, you only show the box, same for the charge controller.

The 48V is the rating of the battery/system Voltage not the PV input Voltage spec.

Thanks for the definitionsThat's not the specs. We need things like Voc, Vmp, Isc, and Imp. Post a link to the panels.

Again, not the needed specs. Post a link to the SCC.

10P means 10 panels in parallel. Once you post links and the needed specs can be found, then recommendations can be made on the best panel setup.

That means 2 parallel strings of 5 panels in series each.

Last edited:

I was looking at doing 12 v, but I might also go for 24. Also it can get to -25 Fahrenheit in the winter and about 100 in the summer.Please also tell us the system voltage you will have (12V, 24V, or 48V) and the lowest temperature ever for where you live.

MichaelK

Solar Wizard

OK, what you are doing is buying random stuff before knowing what you need, or even understanding what you need. You need to stop right now, and first get the real electrical specifications of what you've already bought.

First, open up one of the solar panel packages and look at the sticker on the back. You will see specifications like Voc, Vmp, Isc, Imp. Print those out for us.

Second, open up the MPPT charger box and get it's electrical specifications. We do NOT need things like length, or width. We need maximal volts, maximal amps, size of wire terminals, ect.

The way a modern MPPT controller works is that is acts as a transformer, taking raw, high solar voltage, and transforming down to battery voltage, making extra amps along the way. This is why we need to know the panel specifications. The panels might be wired in series to make 36V, 60V, 90V, ect, then transform it down to battery charging voltage, ~13-14V for a 12V battery, 26-28V for a 24V battery.

The electronics have limits though. Maybe your controllers limit is 100V? That is why you need to open the box and find out what those limits are, because you could easily wire too many panels in series and fry the controller. You want to have the voltage high to cross the 135 foot distance, but not so high that you fry stuff.

It's actually quite important to know what your winter lows are like, because panel voltage goes up as the temperature goes down. Voltage that is fine in summer could damage the controller in winter. We can help you with all these details, but you must supply us with the specifications first.

Stop shopping for electrical cables now. That is just a distraction from the important details. Get the numbers now, and we can recommend the correct sized wires later.

First, open up one of the solar panel packages and look at the sticker on the back. You will see specifications like Voc, Vmp, Isc, Imp. Print those out for us.

Second, open up the MPPT charger box and get it's electrical specifications. We do NOT need things like length, or width. We need maximal volts, maximal amps, size of wire terminals, ect.

The way a modern MPPT controller works is that is acts as a transformer, taking raw, high solar voltage, and transforming down to battery voltage, making extra amps along the way. This is why we need to know the panel specifications. The panels might be wired in series to make 36V, 60V, 90V, ect, then transform it down to battery charging voltage, ~13-14V for a 12V battery, 26-28V for a 24V battery.

The electronics have limits though. Maybe your controllers limit is 100V? That is why you need to open the box and find out what those limits are, because you could easily wire too many panels in series and fry the controller. You want to have the voltage high to cross the 135 foot distance, but not so high that you fry stuff.

It's actually quite important to know what your winter lows are like, because panel voltage goes up as the temperature goes down. Voltage that is fine in summer could damage the controller in winter. We can help you with all these details, but you must supply us with the specifications first.

Stop shopping for electrical cables now. That is just a distraction from the important details. Get the numbers now, and we can recommend the correct sized wires later.

I got rid of the link because I found the actual specs on the parts themselves.That link is for a slightly different panel model number. Look at the back of one of the panels. It should have a sticker with the needed specs.

Similar threads

- Replies

- 3

- Views

- 155

- Replies

- 34

- Views

- 1K

- Replies

- 3

- Views

- 202

- Replies

- 11

- Views

- 507