svetz

Works in theory! Practice? That's something else

One problem with a nut and bolt fastener is that getting the nut tight so it won't come loose puts the bolted together bits under a lot of compressive forces. You can reduce that with lower torque and loctite. Another problem with the solution is that you need access to both sides to hold and tighten unless the nut can be clipped or placed in a channel where it can't turn (or the head in the case of an L bolt).

A snap lock pin on the other hand can hold without those compressive forces. Put a pin in the top and the prongs can't release. But to be easy to use there must be enough of a gap for the prongs to clear the surface and expand so there's not only no compressive force, but typically slop. So vibration can be a problem and cause wear.

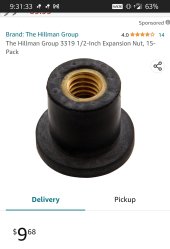

Is there something in between the two solutions? Ideally, something that only needs accessibility from one side? Rivets aren't good as they're not easily removable and you need a lot of space on one side (I have no visibility on one side and about 5" on the other). Right now, L Bolts with loctite is my solution, but wondering if you knew of a different fastener that would be better/cheaper. Looking for something in stainless so it won't rust, needs at least 100 lbf tensile strength.

Thanks in advance!

A snap lock pin on the other hand can hold without those compressive forces. Put a pin in the top and the prongs can't release. But to be easy to use there must be enough of a gap for the prongs to clear the surface and expand so there's not only no compressive force, but typically slop. So vibration can be a problem and cause wear.

Is there something in between the two solutions? Ideally, something that only needs accessibility from one side? Rivets aren't good as they're not easily removable and you need a lot of space on one side (I have no visibility on one side and about 5" on the other). Right now, L Bolts with loctite is my solution, but wondering if you knew of a different fastener that would be better/cheaper. Looking for something in stainless so it won't rust, needs at least 100 lbf tensile strength.

Thanks in advance!

Last edited: