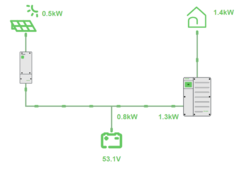

I've been running my 6000xp for about 4 months now and I always notice the gap between the solar input, charge received by the battery and load. I'm trying to figure out if the efficiency is where it should be on this inverter.

For example-

In this screen shot there is 3768 watts coming from PV and a load of 2935 watts. After subtracting load from PV there are a remaining 833 watts that should be charging the battery but only 416 watts are making it there, which is a loss of 417 watts.

417 watts lost is about an 11% loss of the 3768 PV input or meaning the PV circuit is 89% efficient. Is my math correct? How should the efficiency measure out on these inverters?

For example-

In this screen shot there is 3768 watts coming from PV and a load of 2935 watts. After subtracting load from PV there are a remaining 833 watts that should be charging the battery but only 416 watts are making it there, which is a loss of 417 watts.

417 watts lost is about an 11% loss of the 3768 PV input or meaning the PV circuit is 89% efficient. Is my math correct? How should the efficiency measure out on these inverters?