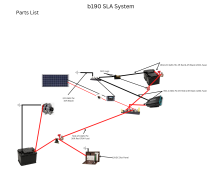

Hi, I'm relocating a house battery to inside the living area of the van in anticipation of upgrading to LiFePO4 battery w/dc-dc charger later. Primary charging will be from the alternator with small solar as secondary. Wire size calculators are looking for the round trip (RT) distance. The starter battery and alternator (in the engine compartment) negatives are wired to the chassis ground. My plan is to run a positive cable to the solenoid/battery separator and tie the house battery to chassis ground near the house battery. So, how do I calculate the RT cable length from the house battery to the solenoid/alternator in this situation?

Tony

Tony