Grasping at straws here, but was wondering if it was normal for a 8mm Amphenol Surlok flange connector (965-SLPHIRBTPSR1) center conductor to wiggle? I have one red and one black connector, with the matching right angle plugs. The center conductor on the red one wiggles a bit like a loose tooth, the black one is rigid. I have only plugged them in a couple times, but worried maybe I cracked it somehow (not obvious to see any damage).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can Amphenol Surlok connectors wiggle?

- Thread starter IGBT

- Start date

I took off the red connector and inspected it. I don't see any broken parts or damage so maybe? it is ok to be loose. The terminal stud and the center conductor appear to be one solid piece of metal with the plastic housing just keeping it centered. I probably worry too much, but you never want to have these things arcing at 120 amps...

robbob2112

Doing more research, mosty harmless

Can you post a picture of the connector and mate in question? With the backshell spun loose so I can see everything?

I am not sure if the power is conducted through the pin or the outer metal ring or the mating teeth.

If I were to guess it is through the pin in which case a wiggle might cause me some hesitation. If you have a flir camera you can check the temp running whatever your normal amps are for a while. If that connector heats up more than the other then you replace it.

If you don't have a FLIR camera they are great for doing post install inspections on connections and fuses to verify everything is operating normally. They also make finding bad connections a breeze.

Other than that run the system and use a laser temp gun to check the temp of the connector shell, pin, mating surface. Then do the same on the other one you said feels fine and compare.

The 'wiggle' you describe would make me wonder if there is something in the center hole not letting it fully seat.

When in doubt - just replace it for safety - there are a few posts on the style connector having issues in the up-in-smoke forum.

In particular this one - not your connector but the same general style.

diysolarforum.com

diysolarforum.com

I am not sure if the power is conducted through the pin or the outer metal ring or the mating teeth.

If I were to guess it is through the pin in which case a wiggle might cause me some hesitation. If you have a flir camera you can check the temp running whatever your normal amps are for a while. If that connector heats up more than the other then you replace it.

If you don't have a FLIR camera they are great for doing post install inspections on connections and fuses to verify everything is operating normally. They also make finding bad connections a breeze.

Other than that run the system and use a laser temp gun to check the temp of the connector shell, pin, mating surface. Then do the same on the other one you said feels fine and compare.

The 'wiggle' you describe would make me wonder if there is something in the center hole not letting it fully seat.

When in doubt - just replace it for safety - there are a few posts on the style connector having issues in the up-in-smoke forum.

In particular this one - not your connector but the same general style.

Beware of the APEXIUM BOX Connectors

Beware of the APEXIUM BOX this happened with the connectors they provided with the box. Also I talked to Apexium and they were very little help.

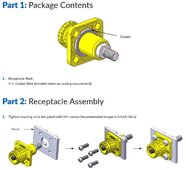

It doesn't have a backshell, that is the other part, which plugs into this part. I looked at it under a microscope and have sort of convinced myself it is allowed to wiggle, even though the other one doesn't. I am however going to replace it with another one from Digikey since I have already taken this one off the boat transom to check it out. It is a fair tight fit to get back there with a wrench so I kind of want to just do this one more time and not often. Here is what the connectors look like:

Attachments

robbob2112

Doing more research, mosty harmless

How many amps do you intend to pass?

I found this

www.westmarine.com

www.westmarine.com

And there are a number of blue sea or other marine brand pass-through connections. The amphenol connector isn't really intended for a wet environment.

More details on what you are doing please

I found this

Ten Deadly Conditions of Boat Electrical Systems | West Marine

West Marine is committed to outfitting your life on the water. With over 250 store locations, 100,000 products in stock, and knowledgeable Associates, trust West Marine for your boating, sailing, fishing, or paddling needs. Shop with confidence - get free shipping to home or stores + price match...

And there are a number of blue sea or other marine brand pass-through connections. The amphenol connector isn't really intended for a wet environment.

More details on what you are doing please

Last edited:

90% of the time, about 10 amps, 5% of the time, 20 amps, 5% of the time, 60 amps, although on full throttle which is too much for this boat, the motor can pull 120 amps.How many amps do you intend to pass?

ricardocello

Watching and Learning

I use Amphenol SurLok Plus for my ESS in the following sizes:

3.6mm Rated 70A Solar PV DC terminations in house AWG 8

5.7mm Rated 125A AC Power from 100A breaker AWG 3

10.3 mm Rated 250A Ground connection to battery rack AWG 2/0

12mm Rated 360A Battery Rack AWG 4/0

I have both lug and threaded receptacles. They wiggle a little without even being attached to anything.

The whole pin wiggles, it isn't just the back, so I'm not worried.

You do have to be careful not to over-torque the threaded ones for sure.

These are high quality expensive connectors. They should have Amphenol stamps in the plastic.

Make sure you avoid the knock-offs which apparently intermittently cause problems.

I have had 0 problems with these connectors, and continue to check them with FLIR when mated.

3.6mm Rated 70A Solar PV DC terminations in house AWG 8

5.7mm Rated 125A AC Power from 100A breaker AWG 3

10.3 mm Rated 250A Ground connection to battery rack AWG 2/0

12mm Rated 360A Battery Rack AWG 4/0

I have both lug and threaded receptacles. They wiggle a little without even being attached to anything.

The whole pin wiggles, it isn't just the back, so I'm not worried.

You do have to be careful not to over-torque the threaded ones for sure.

These are high quality expensive connectors. They should have Amphenol stamps in the plastic.

Make sure you avoid the knock-offs which apparently intermittently cause problems.

I have had 0 problems with these connectors, and continue to check them with FLIR when mated.

Last edited:

ricardocello

Watching and Learning

They have IP67/IP6K9K versions (sealed when mated) which may be appropriate for marine environments.And there are a number of blue sea or other marine brand pass-through connections. The amphenol connector isn't really intended for a wet environment.

The part number called out by the OP (SLPHIRBTPSR1) is sealed to IP67 when mated.

The cable also has to use sealed connectors however.

For those following along:

What is IP6K9K? IP6K9K is a rank of Protection structure which is regulated by DIN40050 Part9 of DIN Standard. 6K-Dustproof:Dust does not enter the interior. 9K-Waterproof: No harmful influence by High-temperature, high-pressure water jet washing.

Yes, as mentioned, these are IP6K9K when mated. 1500V rated, 200 amp (for the 8mm version). I think they have Blue Sea beat.How many amps do you intend to pass?

I found this

Ten Deadly Conditions of Boat Electrical Systems | West Marine

West Marine is committed to outfitting your life on the water. With over 250 store locations, 100,000 products in stock, and knowledgeable Associates, trust West Marine for your boating, sailing, fishing, or paddling needs. Shop with confidence - get free shipping to home or stores + price match...www.westmarine.com

And there are a number of blue sea or other marine brand pass-through connections. The amphenol connector isn't really intended for a wet environment.

More details on what you are doing please

I have both lug and threaded receptacles. They wiggle a little without even being attached to anything.

The whole pin wiggles, it isn't just the back, so I'm not worried.

You do have to be careful not to over-torque the threaded ones for sure.

These are high quality expensive connectors. They should have Amphenol stamps in the plastic.

Make sure you avoid the knock-offs which apparently intermittently cause problems.

I have had 0 problems with these connectors, and continue to check them with FLIR when mated.

Thanks, that does make me feel better. the whole pin was wiggling, from the front to the back, so I think it was always fine, I was just comparing it to the negative (black) identical connector which didn't seem to have any wiggle. Inspecting the part, I see that the plastic housing is just keeping the pin captive, but not holding it firmly locked in the center. This is probably so it mates correctly with the right angle connector. I am sourcing my parts from Digikey, very reliable source in the USA.

ricardocello

Watching and Learning

I use Mouser, same experience.I am sourcing my parts from Digikey, very reliable source in the USA.

Decoding that crazy part numbering is painful. Be sure to check on availability for the sealed versions.

I'm in the "don't care" camp, I'll take sealed or normal, whichever is in stock, because I'm indoors.

You've got to have the sealed ones for sure in marine applications.