can I get away with just 2 wires running 320’ each.

Yes.... and No

First, there needs to be a ground wire so the minimum is 3 wires. However you are probably asking if you need to run the +/- of both strings.

Let's work through it.

The Array Voc is 417V and the 18Kpv can handle up to 600V. That gives you a voltage ratio of 600/417=1.44. That is plenty for any cold temp adjustment.

The Array Isc of two strings is 26.14A. The Isc of MPPT 1 on the 18Kpv is 31A so your 2 strings can go on it. (Note MPPT 2 & 3 could not handle that).

EDIT: I did not calculate Isc for the Bifacial gain. It is possible for these panels to exceed the limit of the 18Kpv if there are 2 strings. See new post below.

So, the two strings can be tied together BUT....

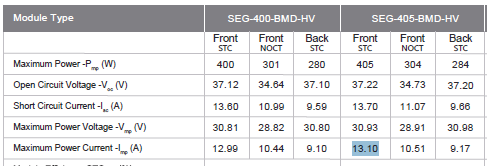

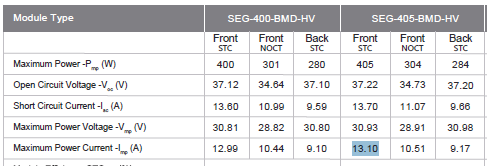

The Imp of the panels is 13.10

The 18Kpv will only use 25A and your array Imp is 13.10 (Front side only) so if the panels are producing at full STC rating the MPPT would clip 1.2A. However, if we look at NOCT, the array will only produce 21.02

Now we have to consider the back-side contribution. If you get a 19% gain, the array Imp is likely to hit 25A even for the NOCT rating.

So.... Will it work with combing the strings at the array? Yes, but the MPPT may not harvest 100% of the energy the arrays could produce depending on conditions.

What should you do?

If it were me, I would have a hard time deciding. The cost of 320ft of wire is painful.... but the thought of *possibly* not taking full advantage of the panels would bug the heck out of me. I would be tempted to spend the money on the wire and use two of the MPPTs on the 18Kpv

Edit: The two strings should be run all the way back to the inverter and use two of the MPPTs. See post 5 below.

First, let's calculate based on a single pair of wires. This is a little bit tricky because we have to decide what the Isc for the combined front/back will be. I will assume a 20% gain. That gives an Isc gain of 10.99A x 1.2 x 2 = 26.38A.

For NEC compliance the wire must handle 1.56 * 26.38 = 41.146A. Looking that up in the NEC ampacity table, we are at 8AWG.

Now we need to look at voltage drop.

Assuming we get a 20% gain the Imp will be 10.44A x 1.2 x 2 = 25.06. The MPP will cap that at 25A and our Vmp is 30.93

Pluging that into a voltage drop calculator, we get 1.756% loss so 8AWG is fine.

Now let's assume you are doing two runs.

The Isc is

10.99 x 1.2 = 13.188A. 13.722 x 1.2 = 16.47 Multiplying that by the NEC 1.55 factor we get

20.44A 25.67. Looking that up in the NEC table we see that you can use

12AWG 10AWG. If the wire has a 90degC rating,

12AWg10AWG is rated for 40A and that is good enough to cover the de-rating of putting all 4 current carrying conductors in a single conduit.

The 25A of the MPPT is no longer the limit so we need to calculate Imp. Assuming a 20% back-side gain we get 10.44 x 1.2 = 12.52. Putting 20.88 and 30.93 into a voltage drop calculator we get a voltage drop of 2.235%. 12AWG for each pair should be fine.