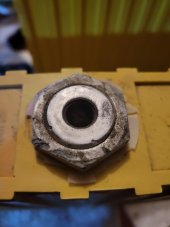

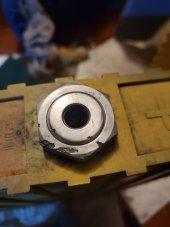

Hello I have a 16s battery pack made from used Winston Thunder Sky 300ah lifepo4 cells. In the two months sitting outside on deck of my boat some terminals corroded (the worse is pictured). As you can see the negative terminal is copper and positive along with the nuts are aluminum. In a marine environment dissimilar metals will cause galvanic corrosion and its avoided by grounding the system to sacrificial zinc anodes. I can't ground the pack directly to my grounding system and I don't know if grounding to the output of the bms will be sufficient or even a good idea? Currently the 48v is ground isolated from the 110vac/12vdc. Does anyone have experience with this? I have thought about adding a zinc directly to my battery.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Galvanic corosion of lifepo4 batteries in marine enviornment

- Thread starter larsenf

- Start date

mikefitz

Solar Wizard

- Joined

- May 28, 2020

- Messages

- 2,979

Why is a battery of any type out on deck?

Adding a chunk of zinc will not achieve anything.

Clean cell terminals and associated hardware , assemble using a special contact great such as NO OX on contact surfaces.

Relocate battery below deck.

Review the complete electrical system in particular the electrical grounds and the relationship with the hull/ prop system protection anodes.

Mike

Adding a chunk of zinc will not achieve anything.

Clean cell terminals and associated hardware , assemble using a special contact great such as NO OX on contact surfaces.

Relocate battery below deck.

Review the complete electrical system in particular the electrical grounds and the relationship with the hull/ prop system protection anodes.

Mike

PreppenWolf

Solar Addict

- Joined

- Oct 10, 2022

- Messages

- 927

Another vote for using either a no ox or at minimum a dielectric grease caked over the terminals.

BobR

Solar Enthusiast

- Joined

- Jan 4, 2021

- Messages

- 305

Always no-ox or equivalent between contact points. Then a protective product over terminals ( https://www.crcindustries.com/products/heavy-duty-corrosion-inhibitor-10-wt-oz.html ). Next construct, or move to, a water tight container/area. You will still need the previous treatment for contacts.Another vote for using either a no ox or at minimum a dielectric grease caked over the terminals.

12VoltInstalls

life passes by too quickly to not live in freedom

At a minimum. Lead acid batteries are the only ones that tolerate environmental exposure and even that is dubious.water tight container

Because air will be the “electrolytic conductor” that approach will essentially do nothing. Zincs on a boat work because they are submerged and part of a “battery” (sic) circuit in banal terms.have thought about adding a zinc directly to my battery

I like to install batt cables clean and dry with nothing to create resistance. After torquing everything I use the CRC dielectric grease or fluidfilm to thoroughly 100% coat the terminals and contacts (on all sides) I wish to protect. I’ve also proven cheap dielectric greased do not last long outdoors. This one has lengevity.

PreppenWolf

Solar Addict

- Joined

- Oct 10, 2022

- Messages

- 927

I use that brand for my CNC business as well. A word of caution, the can is PRESSURIZED. the first time you use it do not use it on the highest setting (adjusts by twisting the large cap). It will go everywhere ?

l00semarble

New Member

- Joined

- Jan 1, 2022

- Messages

- 150

This looks like a textbook case of crevice corrosion, not galvanic corrosion so you are barking up the wrong tree thinking about galvanic protection like zinc. Your terminals are not submerged in an electrolyte which by definition is part of what is necessary to have galvanic corrosion. In simplified terms Crevice corrosion in a metal like aluminum is due to the lack of the oxygen in the stagnating crevice necessary to form a passivating film on the metal. Metals and stainless and aluminum alloys require oxygen to form a oxide layer film which gives them their corrosion resistance. This type of corrosion can/will happen even without dissimilar metals in contact.

I agree with other comments that your batteries should not be on deck and need to be clean and dry at all times. Some NoOx or similar would help but only after getting the batteries shelter.

I agree with other comments that your batteries should not be on deck and need to be clean and dry at all times. Some NoOx or similar would help but only after getting the batteries shelter.

Hello the batteries were decommised from a california funded EV truck trial. They were used for 18 months and then decomissioned and have been stored disconnected outside but under cover in socal since 2017 without corrosion. I only had them on deck for 2 months while renovating my boat and making space for the pack. I believe the salt spray is what got to them. When purchased all had a voltage of 3.175-3.195. After sitting by the sea in 2 months one had dropped to 3.105. They are now in engine room, connected for the first time since I've owned them. The engine room is sealed but if anyone here has cruised on a sailboat you know, salt can and will get anywhere and everywhere. I thoroughly cleaned every cell, polished the terminals with scotchbrite pads and cleaned with acetone. I then used MG chemical's 847 carbon conductive assembly paste on every terminal where it contacts my nickel plated copper buss bars. They are held down with 316 ss bolts. Do you suggest I now use dielectric grease or another prefered chemical on the other exposed metal surfaces? Should the output of my bms be connected the boats grounding (earth) system.

Below are photos of some terminals before and after I cleaned them.

Below are photos of some terminals before and after I cleaned them.

Attachments

Last edited:

12VoltInstalls

life passes by too quickly to not live in freedom

That did look like early onset salt sickness…believe the salt spray is what got to them

12VoltInstalls

life passes by too quickly to not live in freedom

I want to answer this but I’m refraining.Should the output of my bms be connected the boats grounding (earth) system

Have you looked at the ABYC standards online regarding bonding? And not using the hull or fittings to achieve a neg(-) in a circuit? They have specific guidance for bonded hulls versus ‘grounding’ and how to determine what is isolated and what is not.

You mentioned an isolated system and I don’t know your boat; nor am I a certified marine/naval electrician. So I wanted to answer but thought of like three caveats immediately and then decided- not being an expert or certified- I don’t know enough on the guidance to be comfortable advising you in this.

I believe in knowing enough to know what you don’t know… and I know enough to know I don’t know (I just think I know)

I have read all of ABYC standards regarding ac/dc electrical and bonding systems. Sorry I'm interchanging terms with earth and ground since this isn't a marine specific forum. I have completely redone my bonding system to current ABYC standards. I have not seen the new standards relating to lithium as I'm not a member. As far as my boat and system, I have a victron multiplus-ii 48/3000/35 120v, 48v lifepo4 pack from 300ah cells, 5.5kw marine genset, victron 48/12 240w isolated dc/dc converter to run my 12v systems off the 48v pack. All components of the ac system and 12vdc systems are bonded to the hull and shaft zincs (its a fiberglass boat). The 12v negative is bonded. The 48v goes straight to the inverter and isolated dc/dc converter without any bonding. I will also be adding a victron 150/35 mppt which is chassis bonded as are the solar panels.I want to answer this but I’m refraining.

Have you looked at the ABYC standards online regarding bonding? And not using the hull or fittings to achieve a neg(-) in a circuit? They have specific guidance for bonded hulls versus ‘grounding’ and how to determine what is isolated and what is not.

You mentioned an isolated system and I don’t know your boat; nor am I a certified marine/naval electrician. So I wanted to answer but thought of like three caveats immediately and then decided- not being an expert or certified- I don’t know enough on the guidance to be comfortable advising you in this.

I believe in knowing enough to know what you don’t know… and I know enough to know I don’t know (I just think I know)

Last edited:

I only had them on deck for 2 months while renovating my boat and making space for the pack. I believe the salt spray is what got to them.

After sitting by the sea in 2 months one had dropped to 3.105.

Egad. I would not leave my LFP cells overnight on deck. I am not surprised at all that you have damage. Properly installed in the cabin with any grease (I use dielectric, others use no-ox, but truthfully even wheel bearing grease will work) there should not be any issues with the copper vs aluminum posts.

There isn't anything in E-13 regarding grounding or earthing. Being Lithium makes no difference whatsoever. Follow E-11, AC and DC electrical systems.

Looks like the damage is only superficial. After charging the pack some they've come to rest at only a .004v difference. I am quite amazed as I got these very cheap and they had a sharpied date on them of July 2018 which is I assumed the date they were decommissioned and put into storage. I'll have to wait to see what capacity they pull and how they hold up.Egad. I would not leave my LFP cells overnight on deck. I am not surprised at all that you have damage. Properly installed in the cabin with any grease (I use dielectric, others use no-ox, but truthfully even wheel bearing grease will work) there should not be any issues with the copper vs aluminum posts.

There isn't anything in E-13 regarding grounding or earthing. Being Lithium makes no difference whatsoever. Follow E-11, AC and DC electrical systems.