Thergood

New Member

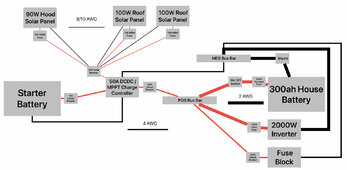

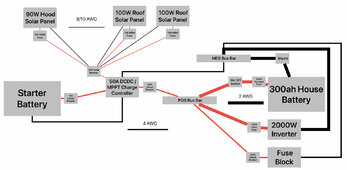

Hey folks - Really appreciate the knowledge on this forum. I'm working a 12v system for my truck bed camper with some solar and DCDC charging. I feel pretty comfortable with everything except the ground situation. Forgive the poor diagram below. Also, please try not to focus on the numbers, I'm still working final calculations for a lot of this.

For some reason I cannot wrap my noggin around this. Is my negative design correct here? Do I need a separate negative cable going from the NEG bus bar to the start battery or common chassis ground at the front of the vehicle?

For some reason I cannot wrap my noggin around this. Is my negative design correct here? Do I need a separate negative cable going from the NEG bus bar to the start battery or common chassis ground at the front of the vehicle?