I am currently making a final decision between Rolls Surrette 2v 5000 series cells and Pylontech 3000c’s for my battery bank. My daily power budget is 25kwh and the battery bank will be sized for two days of autonomy. If I go the rolls route I would be using 24x 2v Cells 2190ah each for 113.9kwh 56.9 usable at 50% DOD 28.4kwh Per day. On the Pylontech side I would use 16x 3000c’s 3.3kwh usable for 53.3kwh usable, 26.3kwh per day. Just for context this will be tied to two sunny islands in split phase a 21kw solar array and a auto start diesel generator with 250 gallon fuel tank. Generator would auto start around 45% dod for the lead acid and 85% for the pylon just to be conservative. Everything will be housed in a temperature controlled solar room 25c 24/7 365. Now my main concern is long term reliability of of the system this will be 100% off grid primary residence. In terms of cycle like rolls are rated at 4200 at 50% did while pylon are rated at 6000 at 90% dod. My main concern with the Pylontech is unknow calendar aging and reliability long term of the bms. I’m looking to hopefully get around 15 years out of these batteries. Any opinions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is my distrust for lithium unfounded?

- Thread starter nicholasm

- Start date

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

Lithium is an umbrella term for many different chemistries.

LFP=lithium iron phospate and LTO=lithium titantate are much safer than the others.

LFP a very popular choice on this forum.

Its my default choice unless there is a specific reason to got with lead acid which would be my first alternate.

One reason to select against LFP is the temperature the batteries will be exposed to.

LFP cannot be charged below 0 Celsius and they age quicker at higher temperatures(roughly > 30 Celcius).

LFP=lithium iron phospate and LTO=lithium titantate are much safer than the others.

LFP a very popular choice on this forum.

Its my default choice unless there is a specific reason to got with lead acid which would be my first alternate.

One reason to select against LFP is the temperature the batteries will be exposed to.

LFP cannot be charged below 0 Celsius and they age quicker at higher temperatures(roughly > 30 Celcius).

OzSolar

Whatever you did, that's what you planned.

My 2 cents...If I go the rolls route I would be using 24x 2v Cells 2190ah each for 113.9kwh 56.9 usable at 50% DOD 28.4kwh Per day.

FWIW, you should design big 2V FLA cells to 80% DOD. The total lifecycle cost and the required footprint is lower when you do it that way. The oft repeated max 50% DOD myth is busted when you actually run the numbers.

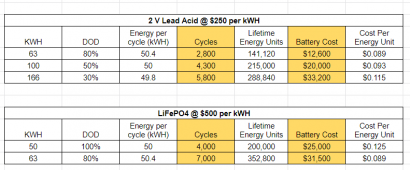

I recently put the below chart together for a customer. The design was 50 usable kWH and key metric is the lowest Cost Per Energy Unit. FLA is still the clear winner if you ignore charge/discharge efficiency, maintenance and self discharge.

Those are just budgetary numbers that I was using. "Your mileage may vary"

FWIW, you should design big 2V FLA cells to 80% DOD. The total lifecycle cost and the required footprint is lower when you do it that way. The oft repeated max 50% DOD myth is busted when you actually run the numbers.

I recently put the below chart together for a customer. The design was 50 usable kWH and key metric is the lowest Cost Per Energy Unit. FLA is still the clear winner if you ignore charge/discharge efficiency, maintenance and self discharge.

That's the most honest thing I've read in years because you included some minor details that may make all the difference. And I'm an LFP guy now, but not unfamiliar with lead-acid.

Yeah, the 50% thing is typically for most thin-plate starter / dual purpose / marine etc and not the TRUE deep cycle with thick plates where with care, you can go lower.

My first thought between choosing between the two for the op would be "are you going to follow the maintenance procedures as specified by Rolls, or not?" For some, it might be too much, but then if one has a lot of experience in a certain field, hey go with what you know!

Vigilant24

New Member

- Joined

- Aug 23, 2022

- Messages

- 119

That's a good way of analyzing things. Three other things:I recently put the below chart together for a customer. The design was 50 usable kWH and key metric is the lowest Cost Per Energy Unit. FLA is still the clear winner if you ignore charge/discharge efficiency, maintenance and self discharge.

Those are just budgetary numbers that I was using. "Your mileage may vary"

View attachment 114841

1) Time value of money. The $18,900 lower initial cost ($31,500 - $12,600) of the lead acid option is money that didn't incur finance charges or (alternatively) was available for other investments. If 2,800 cycles= about 7.6 years, that adds up.

2) The longstanding trend in battery costs ($/wh) has been downward. No guarantees, but it seems likely that when the lead acid batteries are replaced in about 7 years, there may be something better and cheaper available than today's LiFePO4 batteries. Maybe the used packs coming out of EVs built in 2022 will be cheap and perfectly serviceable to power homes in a stationary application for another 7 years.

3) Reliability. (This is will be contentious) There's nothing unknown about lead acid batteries, they are a VERY mature technology. There's no battery-level proprietary BMS to fail. Will it be practical to get someone to troubleshoot a failed BMS on a long-superceded model of LiFePO4 battery in 10 years? Where will the parts come from? If a new battery is required, will the then-available chemistries and BMS architecture play well with all the existing batteries in the installation?

Last edited:

This is a good way of looking at it and something I haven’t considered, I’ll price out that option and see how it works out ~7 range would give time for technology to mature and actually prove itself. Also at 80 DOD I’m realistically only going down to 60% daily (when needed) and 80% on the occasional day where I need the capacity due to weather.My 2 cents...

FWIW, you should design big 2V FLA cells to 80% DOD. The total lifecycle cost and the required footprint is lower when you do it that way. The oft repeated max 50% DOD myth is busted when you actually run the numbers.

I recently put the below chart together for a customer. The design was 50 usable kWH and key metric is the lowest Cost Per Energy Unit. FLA is still the clear winner if you ignore charge/discharge efficiency, maintenance and self discharge.

Those are just budgetary numbers that I was using. "Your mileage may vary"

View attachment 114841

#3 Reliability is the only thing holding me back I see all the benefits of the technology but the bms is really where I struggle putting my fate in the batteries. I spent a considerable amount of time looking at building my own but let that Idea go most due to the fact that they wouldn’t pass inspection and I would never be able to get insurance. And honestly I think I would be more comfortable going that route I could change bad cells or a bms no problem.That's a good way of analyzing things. Three other things:

1) Time value of money. The $18,900 lower initial cost ($31,500 - $12,600) of the lead acid option is money that didn't incur finance charges or (alternatively) was available for other investments. If 2,800 cycles= about 7.6 years, that adds up.

2) The longstanding trend in battery costs ($/wh) has been downward. No guarantees, but it seems likely that when the lead acid batteries are replaced in about 7 years, there may be something better and cheaper available than today's LiFePO4 batteries. Maybe the used packs coming out of EVs built in 2022 will be cheap and perfectly serviceable to power homes in a stationary application for another 7 years.

3) Reliability. (This is will be contentious) There's nothing unknown about lead acid batteries, they are a VERY mature technology. There's no battery-level proprietary BMS to fail. Will it be practical to get someone to troubleshoot a failed BMS on a long-superceded model of LiFePO4 battery in 10 years? Where will the parts come from? If a new battery is required, will the then-available chemistries and BMS architecture play well with all the existing batteries in the installation?

acdoctor

Solar Enthusiast

I believe you will have the ability to charge the Rolls at a higher amperage than recommended. Where as the Pylontech you will be well within the recommended. I like lead, to be it’s simple and robust. Plenty of maintenance though. Checking specific gravity, watering, cleaning terminals. With a single string you would have to shut down to clean any terminals.I am currently making a final decision between Rolls Surrette 2v 5000 series cells and Pylontech 3000c’s for my battery bank. My daily power budget is 25kwh and the battery bank will be sized for two days of autonomy. If I go the rolls route I would be using 24x 2v Cells 2190ah each for 113.9kwh 56.9 usable at 50% DOD 28.4kwh Per day. On the Pylontech side I would use 16x 3000c’s 3.3kwh usable for 53.3kwh usable, 26.3kwh per day. Just for context this will be tied to two sunny islands in split phase a 21kw solar array and a auto start diesel generator with 250 gallon fuel tank. Generator would auto start around 45% dod for the lead acid and 85% for the pylon just to be conservative. Everything will be housed in a temperature controlled solar room 25c 24/7 365. Now my main concern is long term reliability of of the system this will be 100% off grid primary residence. In terms of cycle like rolls are rated at 4200 at 50% did while pylon are rated at 6000 at 90% dod. My main concern with the Pylontech is unknow calendar aging and reliability long term of the bms. I’m looking to hopefully get around 15 years out of these batteries. Any opinions?

On marginal solar days you may get through bulk charge or nearly, but no absorption time. A few of those and you begin to wonder, am I sulfating. Then the absorption phase is long and low amperage.

LFP on the other hand will take full amps until about the last 5%. If you have one or more of those marginal days, well they prefer to not be fully recharge anyway. So long as you recovered enough for the night no big deal.

You still have maintenance but compared to lead you don’t. Then there is the energy efficiency difference. Those Pylontech 10 year warranty is appealing as well. I have two systems one with 37 kw of Rolls 5 years old and one with 7.2 kw DIY LFP 2 years old.

Well, to make the decison even harder, but considering the recent disaster in Florida ..

Are you content with what seems to be only 1 day of use? That is, no additional "days of autonomy" if there is poor weather for a few days? If you add more lead, the more chance that it won't get recharged and sulfate, hence more maintenance. LFP doesn't sulfate, so more is easily accomplished without worry.

And at the best with the fla you'll have to limit your panel amperage to no more than about .15C. (check with manufacturer) With LFP, the typical standard current charge of about .5C, you have the breathing room to expand your panel system. Charges faster, more capacity if you need it with a panel upgrade or if solar insolation is poor for extended periods.

Then there is reconfigurability - if you are a bit older like myself, I can't hump lead around to the other side of the house like I used to if I need to change my main distribution area. With LFP, I can impress my neighbors by whipping around LFP without needing a helper.

So just some practical considerations. So good to see a civilized discussion about this.

Are you content with what seems to be only 1 day of use? That is, no additional "days of autonomy" if there is poor weather for a few days? If you add more lead, the more chance that it won't get recharged and sulfate, hence more maintenance. LFP doesn't sulfate, so more is easily accomplished without worry.

And at the best with the fla you'll have to limit your panel amperage to no more than about .15C. (check with manufacturer) With LFP, the typical standard current charge of about .5C, you have the breathing room to expand your panel system. Charges faster, more capacity if you need it with a panel upgrade or if solar insolation is poor for extended periods.

Then there is reconfigurability - if you are a bit older like myself, I can't hump lead around to the other side of the house like I used to if I need to change my main distribution area. With LFP, I can impress my neighbors by whipping around LFP without needing a helper.

So just some practical considerations. So good to see a civilized discussion about this.

Can you use a generator instead of massively oversizing your battery.

No i don’t think you will get 15 years out of pylontech, i have seen many of them fail inside 5 years.

A well designed LiFePO4 will have more chance of lasting 15 years though. My personal system is approaching 11 years, averaging around 16kwh/day.

No i don’t think you will get 15 years out of pylontech, i have seen many of them fail inside 5 years.

A well designed LiFePO4 will have more chance of lasting 15 years though. My personal system is approaching 11 years, averaging around 16kwh/day.

I have a generator installed for when it is required. I don’t see installing the required bank for my application as oversizing and I am predominantly looking at durability I would prefer light cycling opposed to running batteries hard. Day to day cost effectiveness of operating the system is also a priority so I’m trying to keep my generator run time to a minimum. My operating plan is to spend the money required to build the system (I’m not borrowing for this.) and Invest 300$ a month over the next 10-15 years and use that money to overhaul the system. And repeat. What would you consider a well designed LiFePO4 system?Can you use a generator instead of massively oversizing your battery.

No i don’t think you will get 15 years out of pylontech, i have seen many of them fail inside 5 years.

A well designed LiFePO4 will have more chance of lasting 15 years though. My personal system is approaching 11 years, averaging around 16kwh/day.

I totally agree with you when it comes to charge time and round trip efficiency this the main reason I’m still looking at LFP I’ve split my array in two orientations to extend my solar window and am looking to take advantage of the ac coupling to do as much self consumption as possible so it would help the lead. As for weight I’ve already designed the room around lead with a box rail fitted to the ceiling for the installation of a electric hoist in order to move the batteries aroundWell, to make the decison even harder, but considering the recent disaster in Florida ..

Are you content with what seems to be only 1 day of use? That is, no additional "days of autonomy" if there is poor weather for a few days? If you add more lead, the more chance that it won't get recharged and sulfate, hence more maintenance. LFP doesn't sulfate, so more is easily accomplished without worry.

And at the best with the fla you'll have to limit your panel amperage to no more than about .15C. (check with manufacturer) With LFP, the typical standard current charge of about .5C, you have the breathing room to expand your panel system. Charges faster, more capacity if you need it with a panel upgrade or if solar insolation is poor for extended periods.

Then there is reconfigurability - if you are a bit older like myself, I can't hump lead around to the other side of the house like I used to if I need to change my main distribution area. With LFP, I can impress my neighbors by whipping around LFP without needing a helper.

So just some practical considerations. So good to see a civilized discussion about this.

Attachments

I’ve installed many fully off-grid LiFePO4 systems over the last decade.I have a generator installed for when it is required. I don’t see installing the required bank for my application as oversizing and I am predominantly looking at durability I would prefer light cycling opposed to running batteries hard. Day to day cost effectiveness of operating the system is also a priority so I’m trying to keep my generator run time to a minimum. My operating plan is to spend the money required to build the system (I’m not borrowing for this.) and Invest 300$ a month over the next 10-15 years and use that money to overhaul the system. And repeat. What would you consider a well designed LiFePO4 system?

By far the most cost effective is to size your batteries to cover your maximum nighttime useage plus 20%. (with LiFePO4 use 80% SOC maximum)

Install enough PV to fully recharge your batteries at least 75% of the time.

Any extra power requirements come from generator runtime.

It is simple to calculate the cost difference between extra batteries / PV / hardware, and the diesel cost over a ten year period.

A well designed LiFePO4 system starts with commercial grade cells, and a proven reliable BMS.

I use LiFeTech cells and REC BMS.

Most of the systems i set up use Winston cells and REC BMS.

There are many different factors that will determine system setup - there is certainly not a “one size fits all” solution.

Having been putting these systems together for a long time, and living in a remote region where there are many off-grid systems has given me a good insight into what works long term.

I initially thought the BYD B-Box and Pylontech batteries would be a great idea, but have seen too many of them fail while the simple DIY systems using quality cells just work.

chess-equality

Solar Enthusiast

- Joined

- May 21, 2022

- Messages

- 500

I’ve installed many fully off-grid LiFePO4 systems over the last decade.

By far the most cost effective is to size your batteries to cover your maximum nighttime useage plus 20%. (with LiFePO4 use 80% SOC maximum)

Install enough PV to fully recharge your batteries at least 75% of the time.

Any extra power requirements come from generator runtime.

It is simple to calculate the cost difference between extra batteries / PV / hardware, and the diesel cost over a ten year period.

A well designed LiFePO4 system starts with commercial grade cells, and a proven reliable BMS.

I use LiFeTech cells and REC BMS.

Most of the systems i set up use Winston cells and REC BMS.

There are many different factors that will determine system setup - there is certainly not a “one size fits all” solution.

Having been putting these systems together for a long time, and living in a remote region where there are many off-grid systems has given me a good insight into what works long term.

I initially thought the BYD B-Box and Pylontech batteries would be a great idea, but have seen too many of them fail while the simple DIY systems using quality cells just work.

Where can one buy LiFeTech or Winston cells?

OzSolar

Whatever you did, that's what you planned.

I'd like to know as well.Where can one buy LiFeTech or Winston cells?

Direct from the manufacturer is best for LiFeTech.I'd like to know as well.

There are many companies that stock Winston. EVlithium have been selling them for a long time.

Quattrohead

Solar Wizard

I am not a 247 salesman and do not have these batteries !!!!

Why don't these come up in conversation on here ?

12kWH Silicate Battery

Why don't these come up in conversation on here ?

12kWH Silicate Battery

OzSolar

Whatever you did, that's what you planned.

Because they aren't Lithium. Ha. Seriously though I've wondered the same thing.I am not a 247 salesman and do not have these batteries !!!!

Why don't these come up in conversation on here ?

12kWH Silicate Battery

LifePO4 @500 per kWH?! My rack was less than $300. And I get to take off 30% of that, so about $200 per kWH.My 2 cents...

FWIW, you should design big 2V FLA cells to 80% DOD. The total lifecycle cost and the required footprint is lower when you do it that way. The oft repeated max 50% DOD myth is busted when you actually run the numbers.

I recently put the below chart together for a customer. The design was 50 usable kWH and key metric is the lowest Cost Per Energy Unit. FLA is still the clear winner if you ignore charge/discharge efficiency, maintenance and self discharge.

Those are just budgetary numbers that I was using. "Your mileage may vary"

View attachment 114841

OzSolar

Whatever you did, that's what you planned.

Way to go! Where can we send your trophy?LifePO4 @500 per kWH?! My rack was less than $300. And I get to take off 30% of that, so about $200 per kWH.

Seriously though, why did you chose to ignore "your mileage may vary"?

I'm building a 42kWH pack for just a bit over $250/kWH and I will write 100% of that off as a business expense. That's $0 per kWh. I'll just keep the trophy.