relliott64

New Member

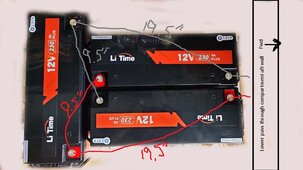

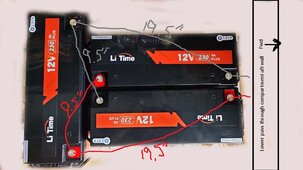

Hello all. I have replaced my 2ea. 12v lead acid batteries with 3ea. 230ah lithium batteries wired in parallel. I am going to be relocating them just behind my 5th wheel RV's lower pass through, aft wall. There is not a ton of space back there due to all the existing plumbing so I am thinking about positioning the batteries as in the attached picture. Do they appear to be wired correctly so I'll get equal draw from each battery? If I did it this way, I'd need 2ea cables at 9.5" and 2 more at 19.5". Should I increase the length of the 2ea shorter cables so that all of them are the same length? I plan to eventually hook up a 2000w PSW inverter to the batteries for the few times a year where we may be camping without power. I'm just going to running a heavy cord from the 20amp outlet on the inverter the the 50amp plug on the rv with adapters. Thanks for any and all input.