heirloom hamlet

life my way

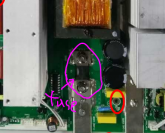

Has anyone ever replaced or does anyone have knowledge if it is possible to replace the internal inverter fuse in an LV2424?

For some time, I have felt like the unit cannot take the load it once could.

It is currently not being pushed to or beyond what it was designed to do, yet it does a thermal stoppage routinely on relatively light loads. I'm wondering if pushing a heavier load in the past (right at it's 2400w limit) could have impacted the endurance of it's internal inverter fuse.

Is that possible, can fuses degrade and lose their umph while remaining someone operational?

For some time, I have felt like the unit cannot take the load it once could.

It is currently not being pushed to or beyond what it was designed to do, yet it does a thermal stoppage routinely on relatively light loads. I'm wondering if pushing a heavier load in the past (right at it's 2400w limit) could have impacted the endurance of it's internal inverter fuse.

Is that possible, can fuses degrade and lose their umph while remaining someone operational?