garybryan33

New Member

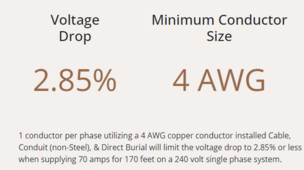

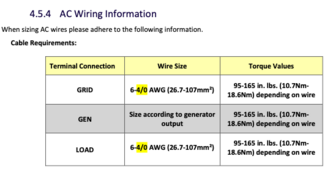

The EG4 18kv will live In the carport, 170 feet away from the critical loads panel it will feed. The subpanel will have a 70-amp (80-amp if possible) main breaker. Do I need #2AWG or would #4 AWG for the approx 170tf run? A bit confused on whether the max voltage drop of 3% is for continuous only.