McKravitts

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 567

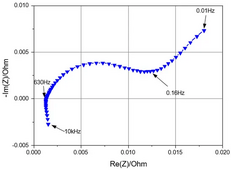

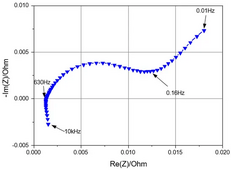

The Impedance of a battery is a function of the frequency used to measure it.

There doesn't appear to be any standardized frequency used in the industry. If anyone knows of any standard methods, please respond.

Without any standerdized methods manufactures can use any frequency they want. As mentioned in a few preceeding post, impedance is not a good way to eveluate a battery overall.

Impedance Characterization and Modeling of Lithium-Ion Batteries Considering the Internal Temperature Gradient

There doesn't appear to be any standardized frequency used in the industry. If anyone knows of any standard methods, please respond.

Without any standerdized methods manufactures can use any frequency they want. As mentioned in a few preceeding post, impedance is not a good way to eveluate a battery overall.