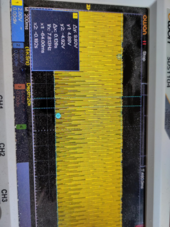

But your peak isn't 9.8v, your peak-to-peak is 9.8v. You still need to divide by two.

argg. I both love it it when my superiors are correct all(most off) the time(s) else risk me running after my own tail all the time.

But also hate it as it is slowing me down/ or even preventing me to get to where I want to get.

But this is just a joke of sorts.

I really respect the pushback otherwise we end up with garbage for a whole new generation of unsuspecting readers to just blindly follow.

Anyway Gary, I think you know more about how this stuff works that the internet does because when I started measuing your statment with the setup below I could do not nothing else than flame and admit you are correct.!!

Now do you see how close the word admit is to another one that conveys my emotions? hahah

----

damn{insert characters}....

-----

My lord I hate infuencers!

I'll ask again!

. How does one protect their offspring these days from this wildfire of nonsense?

Anyway back to the matter at hand.

Here we have the most recent configuration preparations for what I think in the meantime is a sane way of tackling this problem.

I have now stored into the freezer the simple method I proposed earlier. Rest assured it will thaw again at one point or another. I guess we all know by know that ideas will mostly be re entertained if not properly laid to rest. Just for the sake of being able to let things go.

Was it easy for me to admit that my wild ideas were misguided?

...

..

No of course not. I hated that. I had hoped to be the next genius out there.

..

did that determine me to understand that that is is only a bonus which we should not expect and that the goal should remain the goal?

(without a second thought) of course. lets get this on. where ever this leads us. I will take my pride from the fact that I was even able to get things done with the help of so many of you.

-----

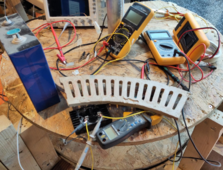

What we have here is a setup that can measure many data points in a single run. With the exception of the data points to be taken with an open circuit.

Now the start point is a Lifep04 cell single cell, But it is easy enough to add to it in series step by step.

Please scrutinize the following data points I think are relevant for the creation of solid charts.

If this is going to be the new standard then I am a bit sad.

Boy I wanted it to be just simple!!! even though I knew it was going to be HARD. I just once again thought that maybe with a little weird thinking perhaps things could become less difficult.

Hahha. well at least I keep trying.

Here goes

* motor Hz

* (open circuit) (Hz) while at vAC (below)

* (open circuit) vAC

* (closed circuit) vDC (after rectification)

* (closed circuit) aDC (after rectification)

* Coil temp (celsuis)

Now I already know I forgot one or 2. Please help me out here.