Hi all,

I am considering purchasing the Ecoflow wave and I cannot seem to figure out if I will be able to hook it up to my existing 200AH 24V LifePo4 battery bank. I have asked Ecoflow and they either don't have trained staff or they are told to say no without really thinking through my question.

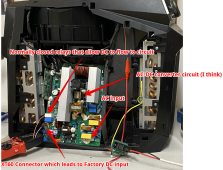

As you will see, the Wave can run off of a 1000Wh battery pack that connects via a small cable to a port on the unit. I also know that the Wave can be powered by the Ecoflow Delta Max with a cable called the "Extra Battery Cable". This goes into the DC output of the Delta Max, and right into the DC input for the Ecoflow Wave, powering the unit to the 400ish watts that it runs at.

My question is, can I simply purchase this extra battery cable and create something like a fused anderson powerpole connection to my 24V 200AH bank? The Delta prodduct support team is being very cagey about voltages of units - they only speak in watts. I can't seem to figure out if the Delta Max actually puts out 12v/24v/48v from it's "extra battery cable" port. I do know it says it can handle up to 3400 watts, at at that AWG, I would highly doubt it's 12V, but maybe it's 48V and the Wave won't run unless I change my bank configuration to be 48V.

I would really like to use this unit, but I have no need for one of their Delta products with my existing setup. If i ever do upgrade it'll just be to add another 1-2 Lifepo4 batteries to my existing setup.

P.S I'm not concerned about runtimes and power draw. I'll use a generator if needed, or I'll splurge and add some solar panels and 24V 200AH to my setup.

Thanks everyone for the input.

-Glen

I am considering purchasing the Ecoflow wave and I cannot seem to figure out if I will be able to hook it up to my existing 200AH 24V LifePo4 battery bank. I have asked Ecoflow and they either don't have trained staff or they are told to say no without really thinking through my question.

As you will see, the Wave can run off of a 1000Wh battery pack that connects via a small cable to a port on the unit. I also know that the Wave can be powered by the Ecoflow Delta Max with a cable called the "Extra Battery Cable". This goes into the DC output of the Delta Max, and right into the DC input for the Ecoflow Wave, powering the unit to the 400ish watts that it runs at.

My question is, can I simply purchase this extra battery cable and create something like a fused anderson powerpole connection to my 24V 200AH bank? The Delta prodduct support team is being very cagey about voltages of units - they only speak in watts. I can't seem to figure out if the Delta Max actually puts out 12v/24v/48v from it's "extra battery cable" port. I do know it says it can handle up to 3400 watts, at at that AWG, I would highly doubt it's 12V, but maybe it's 48V and the Wave won't run unless I change my bank configuration to be 48V.

I would really like to use this unit, but I have no need for one of their Delta products with my existing setup. If i ever do upgrade it'll just be to add another 1-2 Lifepo4 batteries to my existing setup.

P.S I'm not concerned about runtimes and power draw. I'll use a generator if needed, or I'll splurge and add some solar panels and 24V 200AH to my setup.

Thanks everyone for the input.

-Glen