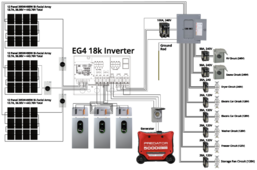

Hi everyone, I'm doing my first off grid install for my own home. I would like to get some feedback on what I have so far from anyone generous enough to provide it.

This is not going to be connected to grid power and will support an RV and some minimal requirements while we build an off grid home. I'm using Sketchup Web to diagram the system, my apologies, I can't seem to get the line colors to change which is why they are all black instead of red, black, grey and green. I've already bought the panels, inverter, and batteries from Current Connected and Signature Solar, so feedback on using different components won't be super helpful. I haven't purchased any of the electrical hardware and components yet.

Some questions I would love more feedback on to make sure I have the concepts right:

- Is my main breaker seem reasonable on the electrical panel? I see 60A used a lot with 18k in other designs, is that due to the max output of the inverter?

- I think I have sizing right on my solar arrays for each MPPT for the EG4 18k based on what I've learned from the manual all the folks here in reading through other posts, but please sanity check me

- Does it make more sense to add a generator to the 18k or via Chargeverter setup, I can use one or both of my Predator 5000 generators with a pairing kit. They are inverter generators so provide clean power. The guys at Current Connected said forego the Chargeverter, but I see a lot of feedback on needing enough power from the generators to run all loads + charge the batteries, which might push the Predator generators past their limit?

- Should I be incorporating Surge Protection Devices (SPD), like from Midnight Solar?

- I'm assuming I should add a PV Disconnect as well between the arrays and inverter?

Link to Generator: https://www.harborfreight.com/5000-...ote-start-and-co-secure-technology-70143.html

Link to Parallel Kit: https://www.harborfreight.com/rv-ready-50-amp-inverter-generator-parallel-kit-58374.html

For context, eventually when the home is built, I will be adding another EG4 18k, three more wall mount batteries, with 36 more of the Hyperion panels. All inverters and batteries will be installed in a shipping container. Appreciate any feedback!

This is not going to be connected to grid power and will support an RV and some minimal requirements while we build an off grid home. I'm using Sketchup Web to diagram the system, my apologies, I can't seem to get the line colors to change which is why they are all black instead of red, black, grey and green. I've already bought the panels, inverter, and batteries from Current Connected and Signature Solar, so feedback on using different components won't be super helpful. I haven't purchased any of the electrical hardware and components yet.

Some questions I would love more feedback on to make sure I have the concepts right:

- Is my main breaker seem reasonable on the electrical panel? I see 60A used a lot with 18k in other designs, is that due to the max output of the inverter?

- I think I have sizing right on my solar arrays for each MPPT for the EG4 18k based on what I've learned from the manual all the folks here in reading through other posts, but please sanity check me

- Does it make more sense to add a generator to the 18k or via Chargeverter setup, I can use one or both of my Predator 5000 generators with a pairing kit. They are inverter generators so provide clean power. The guys at Current Connected said forego the Chargeverter, but I see a lot of feedback on needing enough power from the generators to run all loads + charge the batteries, which might push the Predator generators past their limit?

- Should I be incorporating Surge Protection Devices (SPD), like from Midnight Solar?

- I'm assuming I should add a PV Disconnect as well between the arrays and inverter?

Link to Generator: https://www.harborfreight.com/5000-...ote-start-and-co-secure-technology-70143.html

Link to Parallel Kit: https://www.harborfreight.com/rv-ready-50-amp-inverter-generator-parallel-kit-58374.html

For context, eventually when the home is built, I will be adding another EG4 18k, three more wall mount batteries, with 36 more of the Hyperion panels. All inverters and batteries will be installed in a shipping container. Appreciate any feedback!