Boron

New Member

I saw this on another members post but lost the link? Maybe some knows?

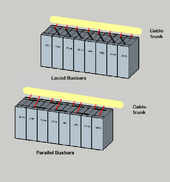

We all know what a mess you can end up with, connecting all those cell volt little wires back to the BMS, so here's something so obvious and so much more tidy. What do you think? Laced connections (longer flexible busbars, or cable/ring terms?) From a mechanical view I find the hard connection using solid busbars puts stresses on the M6 studs and the sealing with the casing? Doesnt feel right. But those crimped multi-leaf versions are $$$. BTW this is what I use cos Im cheap. Its a copper tube wall clamp ca 10p ea. The csa is ca 3mm^2 so good for 50A, - my load max. Double up for 100A? Love your Plumber.

We all know what a mess you can end up with, connecting all those cell volt little wires back to the BMS, so here's something so obvious and so much more tidy. What do you think? Laced connections (longer flexible busbars, or cable/ring terms?) From a mechanical view I find the hard connection using solid busbars puts stresses on the M6 studs and the sealing with the casing? Doesnt feel right. But those crimped multi-leaf versions are $$$. BTW this is what I use cos Im cheap. Its a copper tube wall clamp ca 10p ea. The csa is ca 3mm^2 so good for 50A, - my load max. Double up for 100A? Love your Plumber.