garybryan33

New Member

This is for an off-grid system powering a garage. The system consists of 1 18kpv and 2 wall mount batteries.

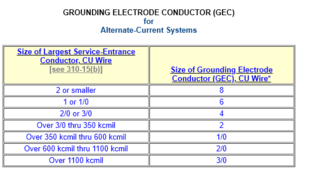

1. The load panel is 70 feet from the inverter; I will be running 4awg, 2 feeds, and a neutral. Do I need to run a 4awg ground wire as well or could it be smaller?

2. The grounding rod will be located at the load panel. What size wire should be run from the panel to the grounding rod?

3. Should the solar array mounting rail ground be run to the inverter, the load panel ground, or straight to ground with its dedicated rod?

Previous schematics for the 18kpv recommended a grounding rod dedicated to it. I don't see that on the latest schematics, anyone with some insight?

Thank you all for your help.

1. The load panel is 70 feet from the inverter; I will be running 4awg, 2 feeds, and a neutral. Do I need to run a 4awg ground wire as well or could it be smaller?

2. The grounding rod will be located at the load panel. What size wire should be run from the panel to the grounding rod?

3. Should the solar array mounting rail ground be run to the inverter, the load panel ground, or straight to ground with its dedicated rod?

Previous schematics for the 18kpv recommended a grounding rod dedicated to it. I don't see that on the latest schematics, anyone with some insight?

Thank you all for your help.