kolek

Inventor of the Electron

- Joined

- Sep 29, 2021

- Messages

- 796

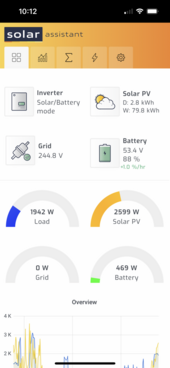

Two identical batteries in 2P16S setup.

Been sitting in parallel for 3 weeks.

During charging, 1 is charging at 16A, the other is charging at 25A. Voltage is identical between the 2.

This is according to the JK-BMS.

Verified the JK-BMS amperage difference with a clamp meter. The readings are accurate. Gap is real.

Checked Victron Smart Shunt, and the total amperage is 16+25=41A, so that checks out as well.

Everything is identical between these batteries. Same wire lengths, same wire. Same BMS settings.

How is this possible and if it's an indication of a problem, what would the problem be?

Been sitting in parallel for 3 weeks.

During charging, 1 is charging at 16A, the other is charging at 25A. Voltage is identical between the 2.

This is according to the JK-BMS.

Verified the JK-BMS amperage difference with a clamp meter. The readings are accurate. Gap is real.

Checked Victron Smart Shunt, and the total amperage is 16+25=41A, so that checks out as well.

Everything is identical between these batteries. Same wire lengths, same wire. Same BMS settings.

How is this possible and if it's an indication of a problem, what would the problem be?

Last edited: