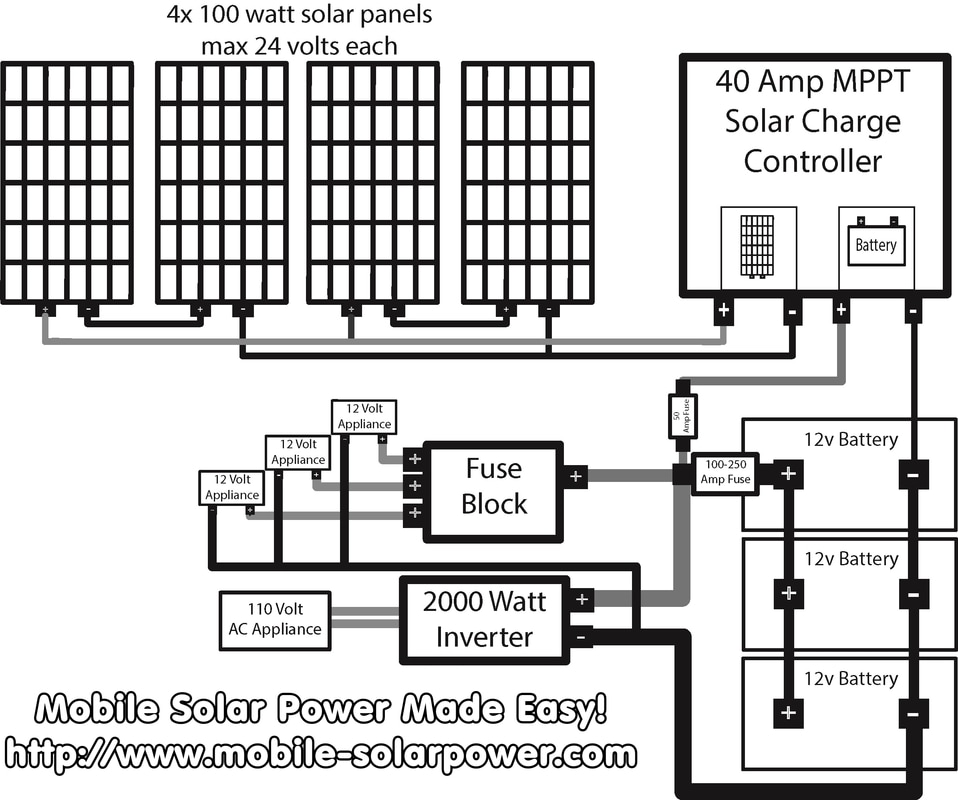

System is 12v, 4 Panel 100W, 18v-21.6v, 5.5A-6.11A. 2 Series, 2 Parallel.

Apparently rule of thumb is to size it to be 2/3 max output. 400W / 14.4 Volts = 27.8A. If it's sized at 2/3, that would require a 41A output. I think 40 would be close enough.

However, Victron's calculator says to use a 30A controller.

I would think that Victron knows what they're doing. Are their controllers that more efficient?

So, do I go with a 100/30 or do I go higher? There doesn't seem to be a 40A, so 100/50 is the next step. Any thoughts would be appreciated...

Apparently rule of thumb is to size it to be 2/3 max output. 400W / 14.4 Volts = 27.8A. If it's sized at 2/3, that would require a 41A output. I think 40 would be close enough.

However, Victron's calculator says to use a 30A controller.

I would think that Victron knows what they're doing. Are their controllers that more efficient?

So, do I go with a 100/30 or do I go higher? There doesn't seem to be a 40A, so 100/50 is the next step. Any thoughts would be appreciated...